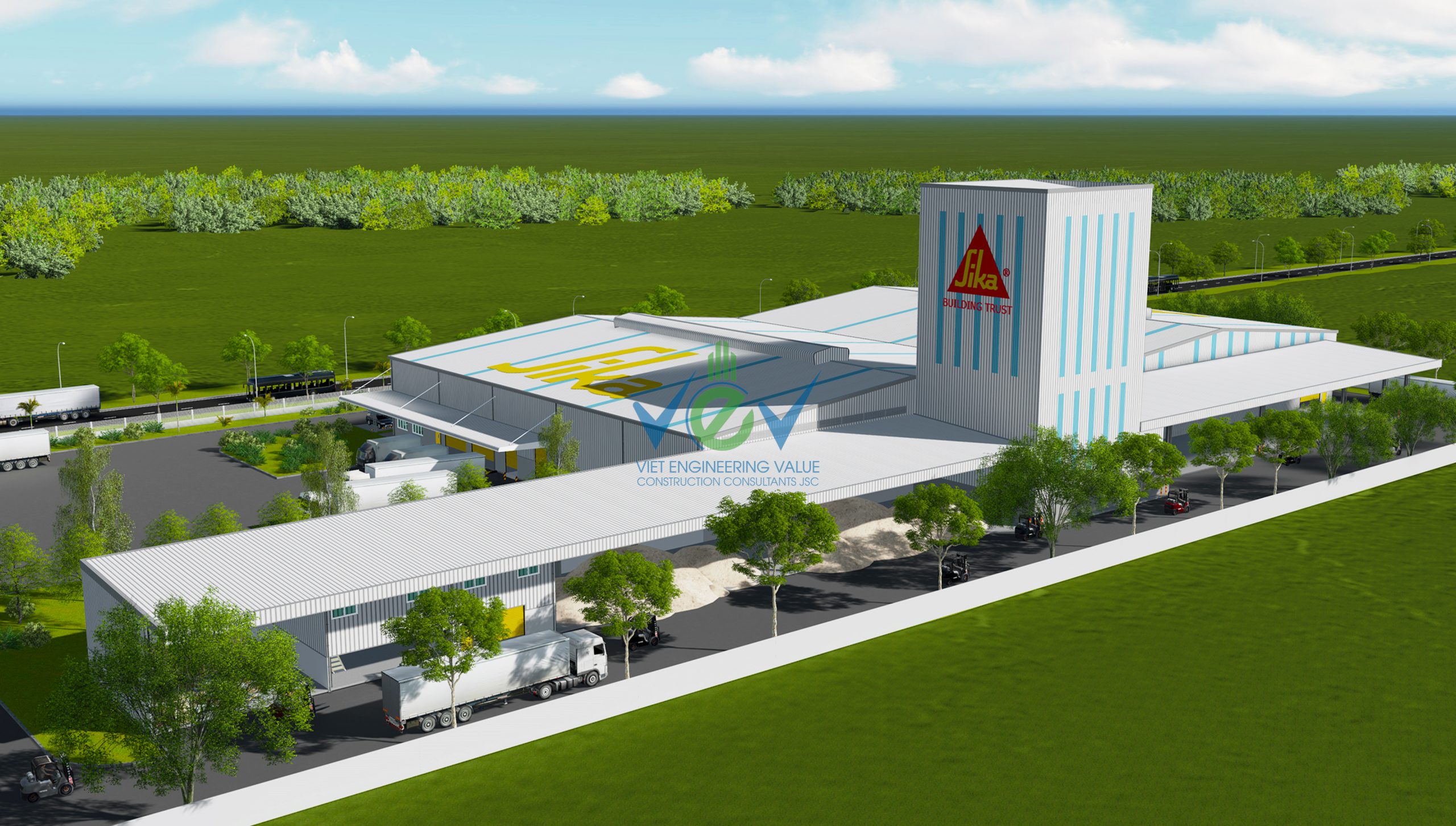

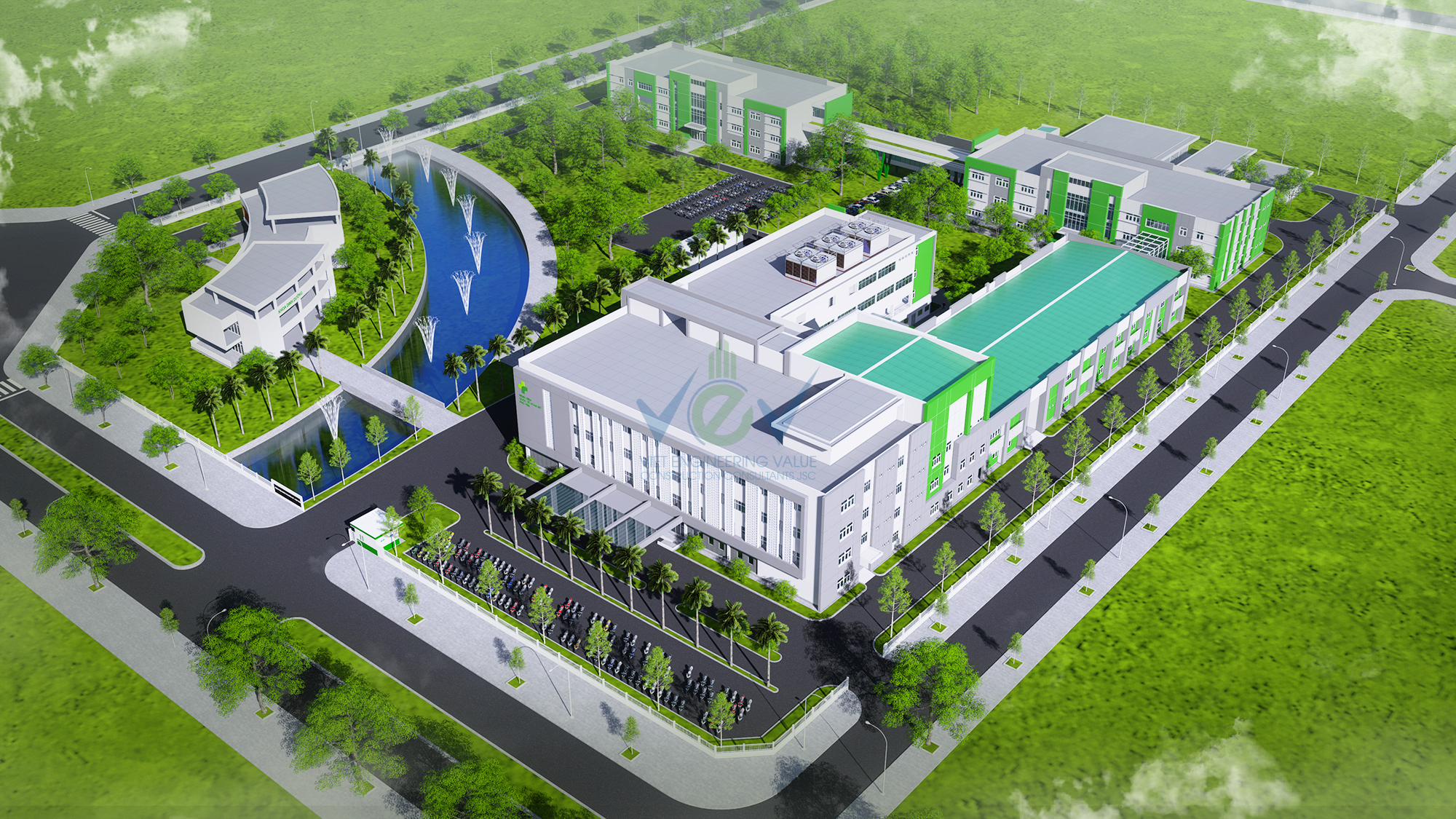

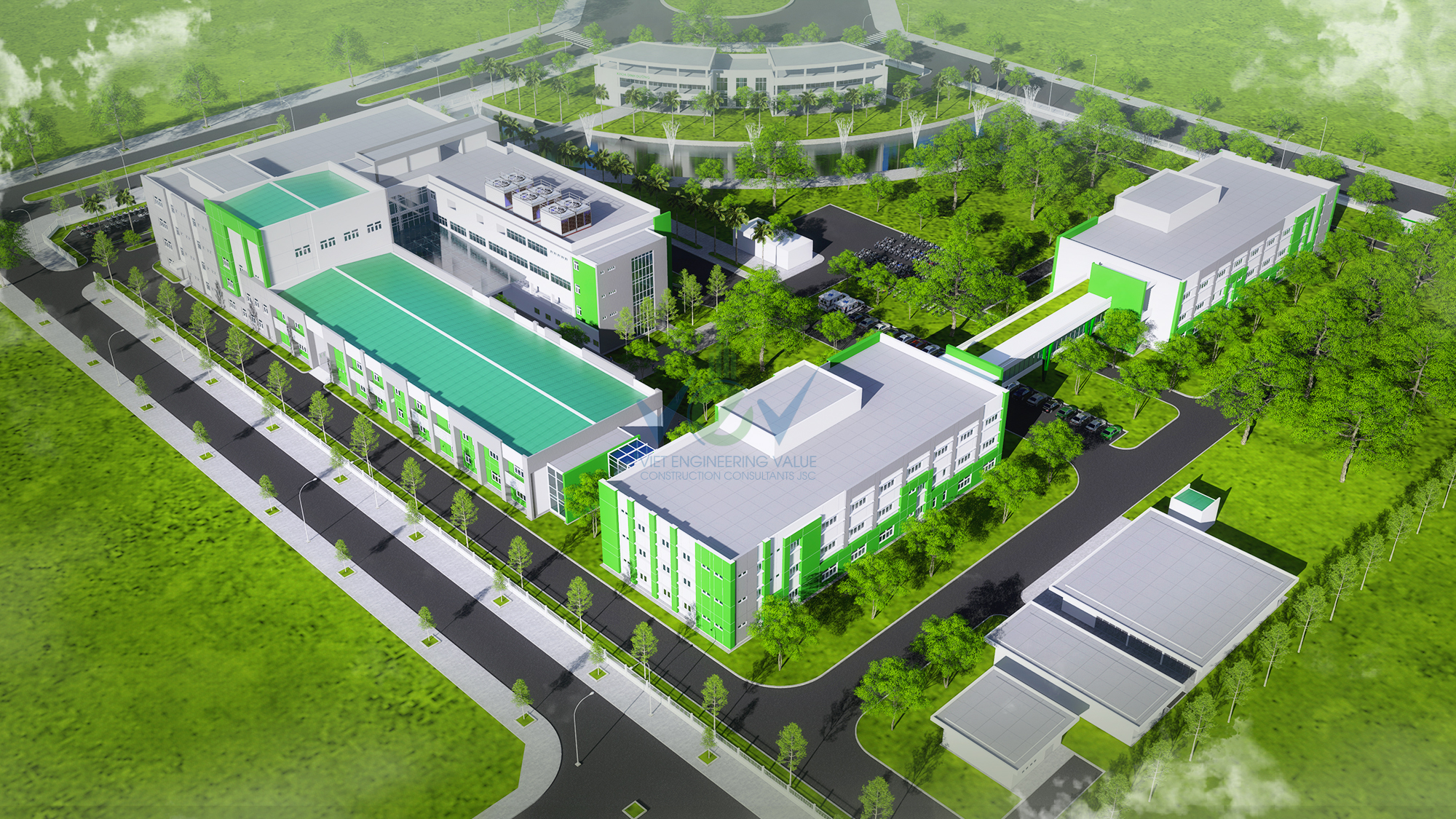

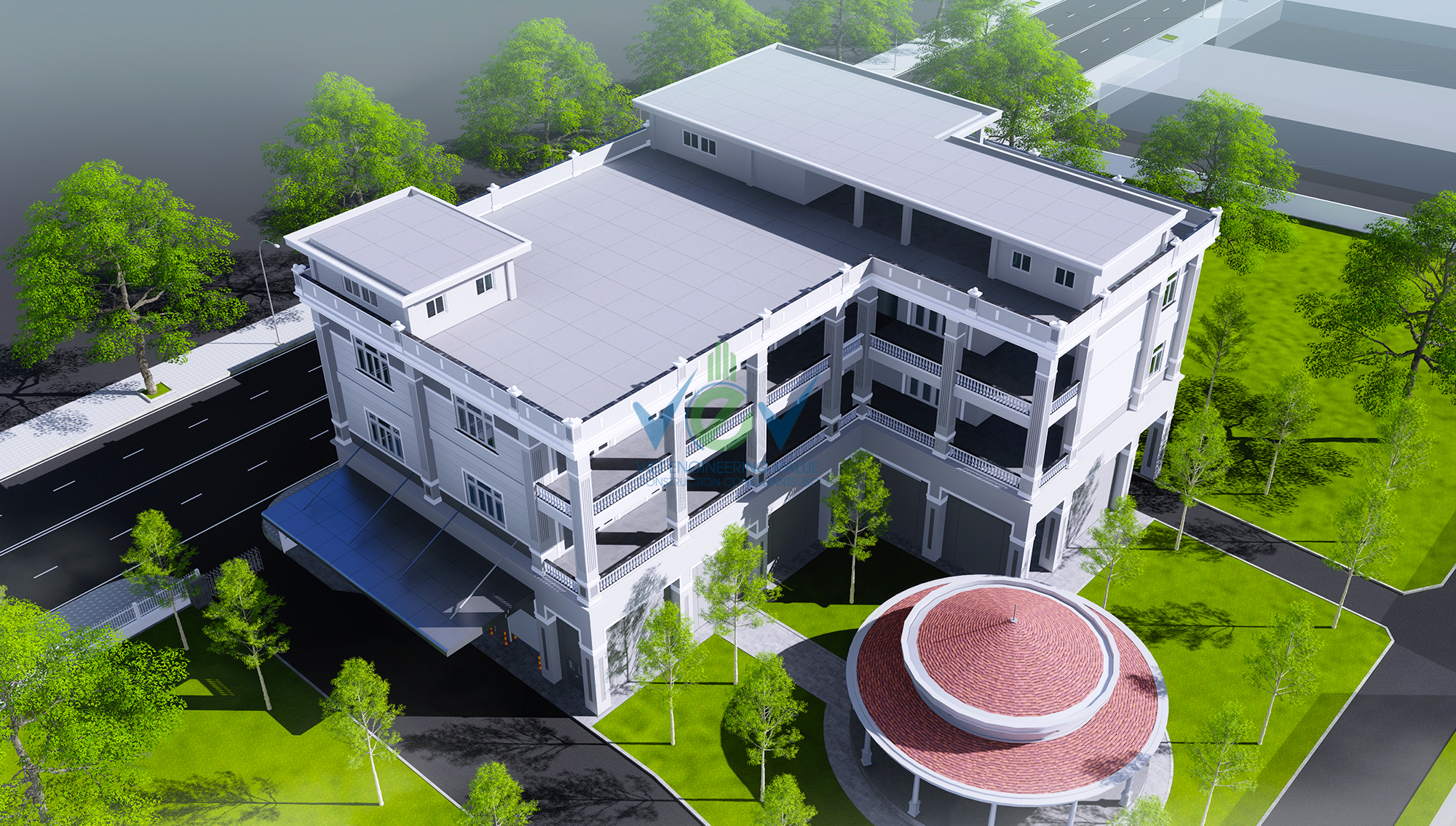

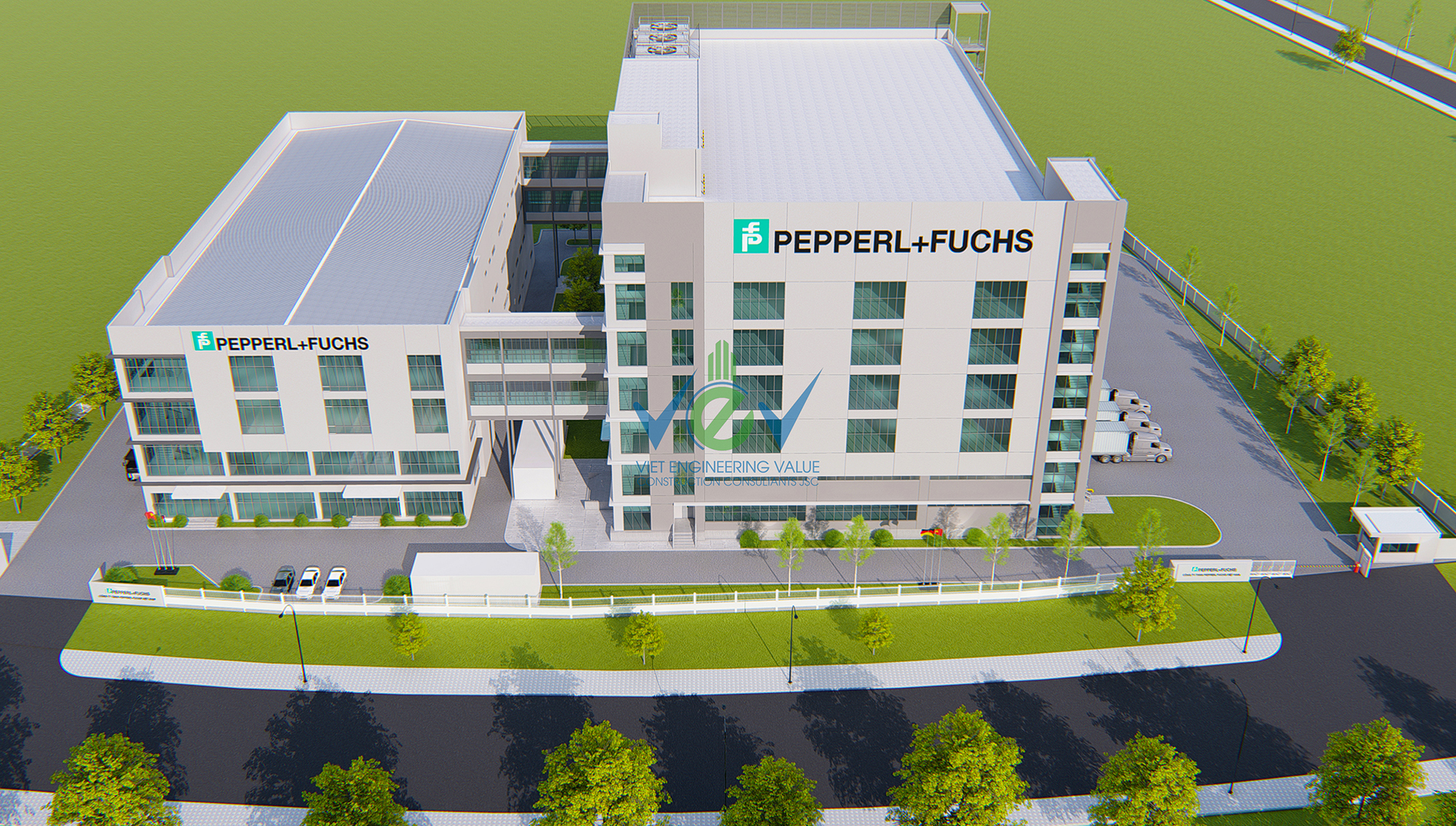

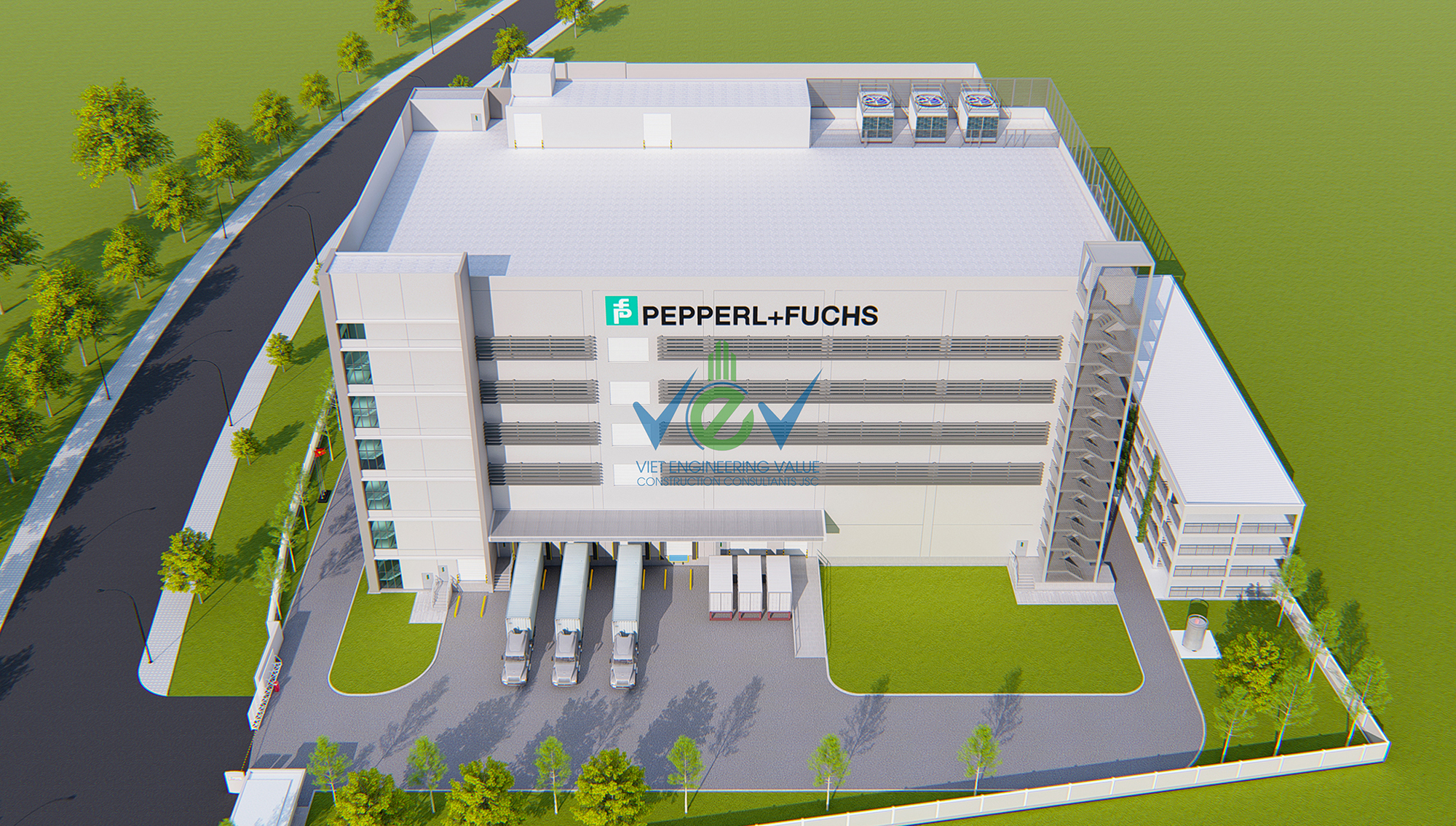

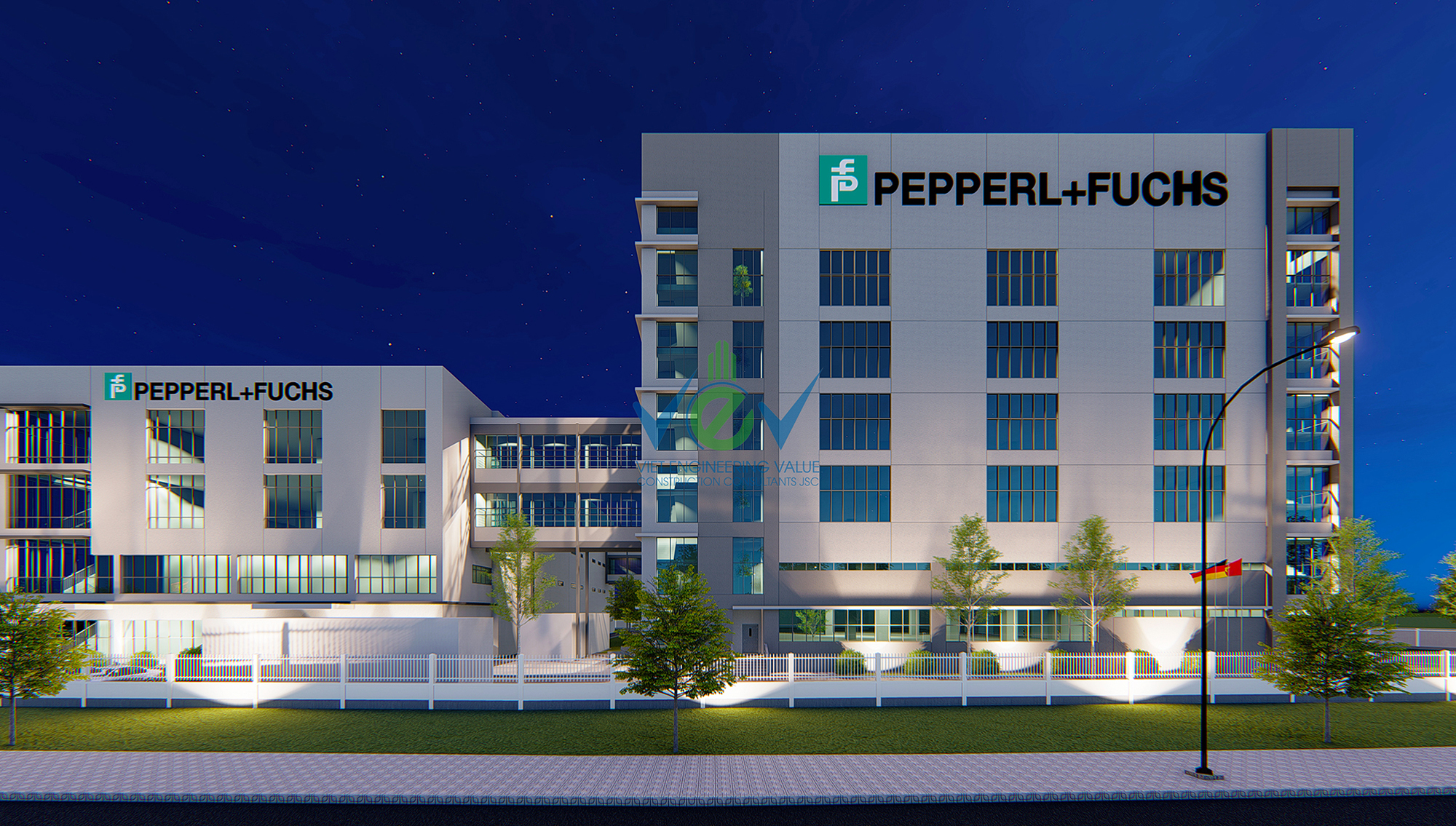

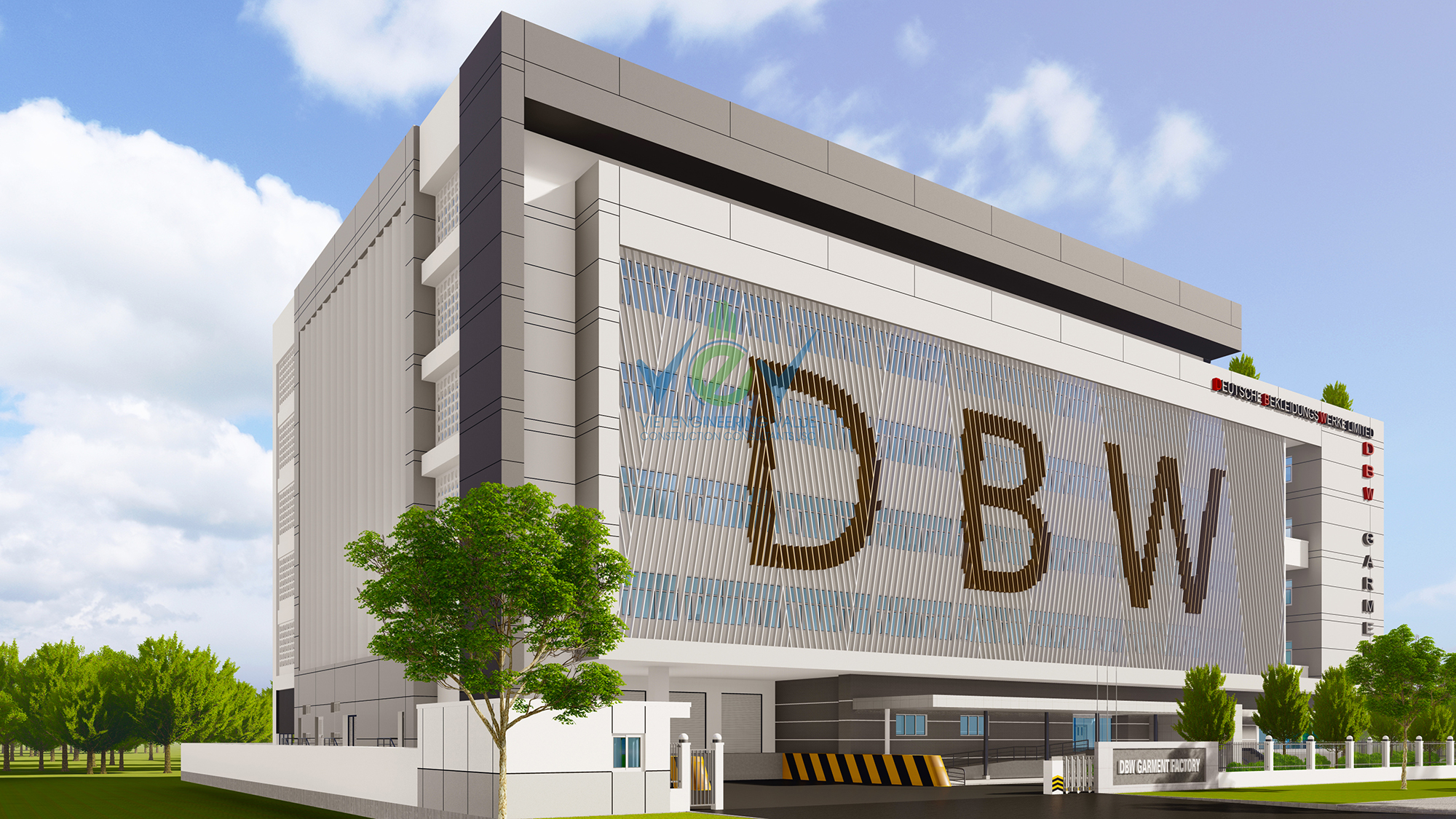

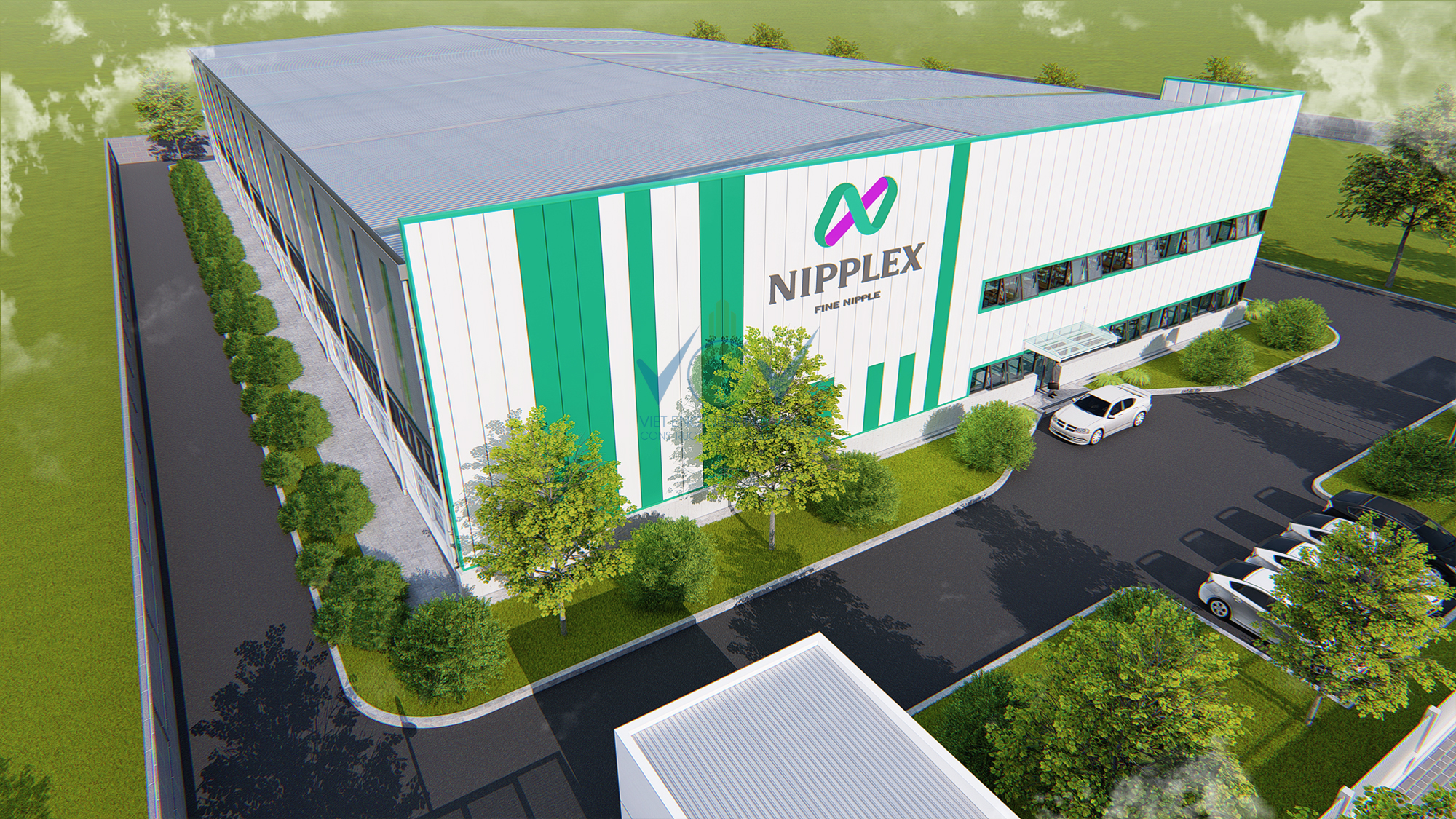

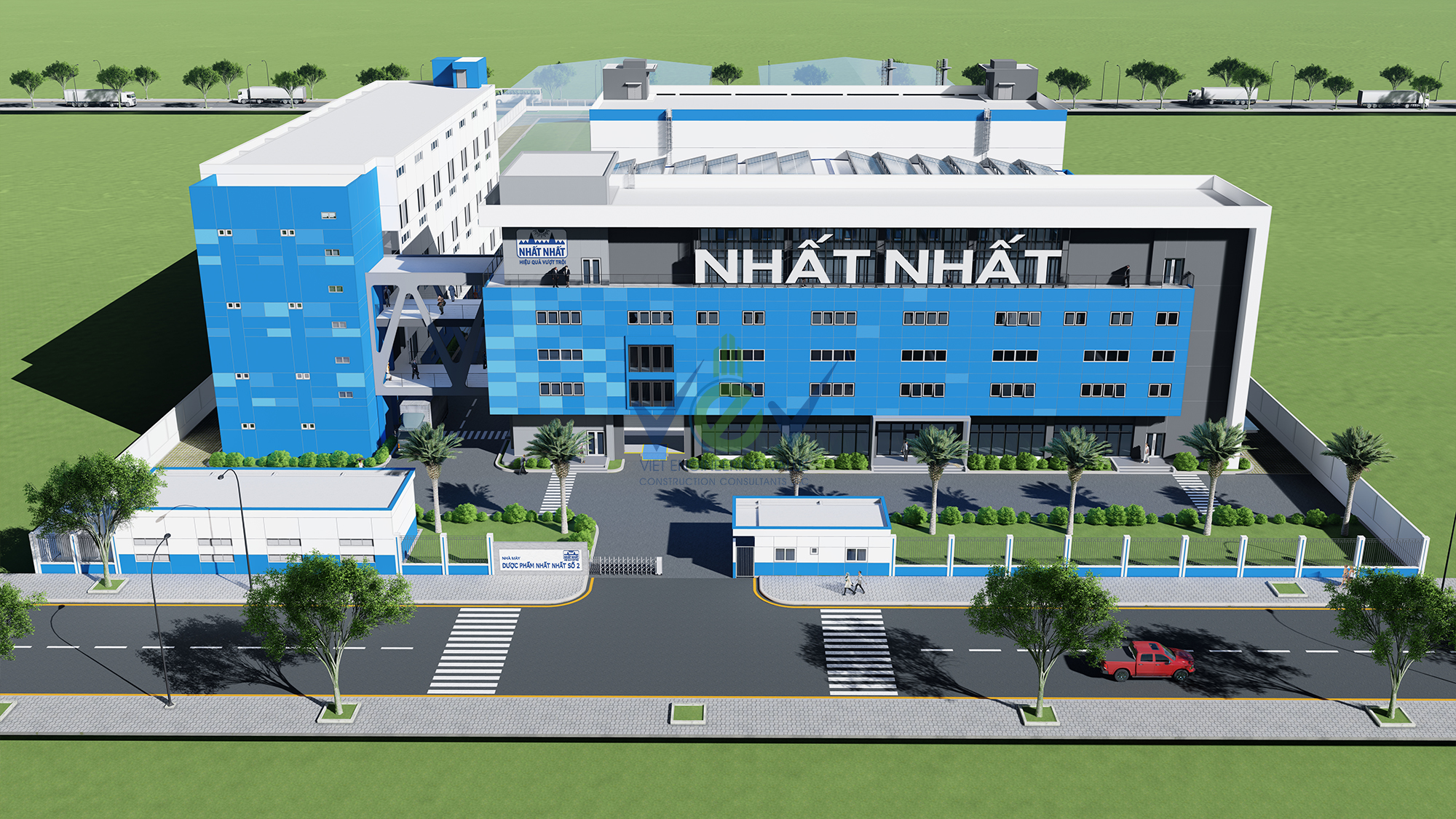

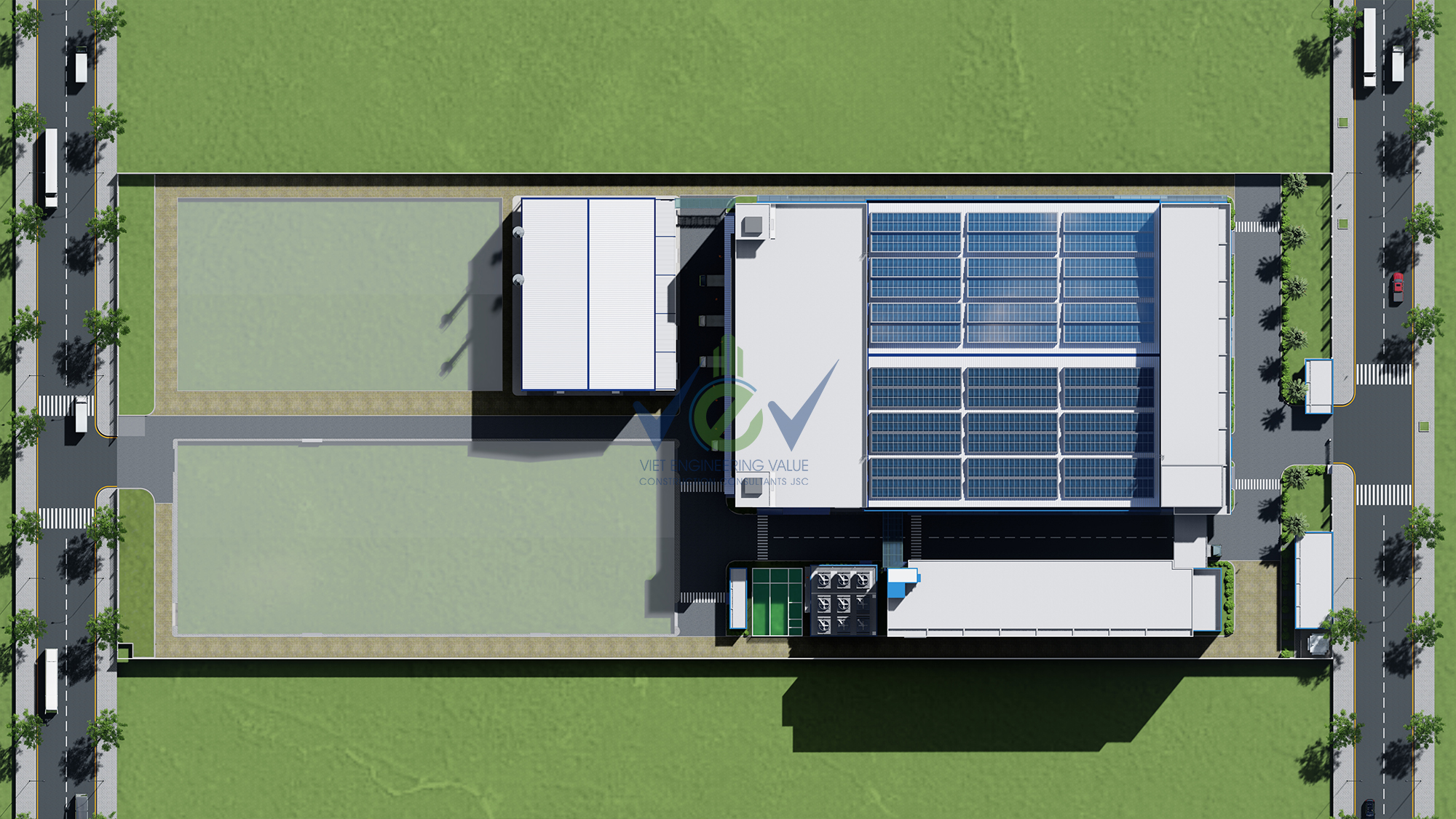

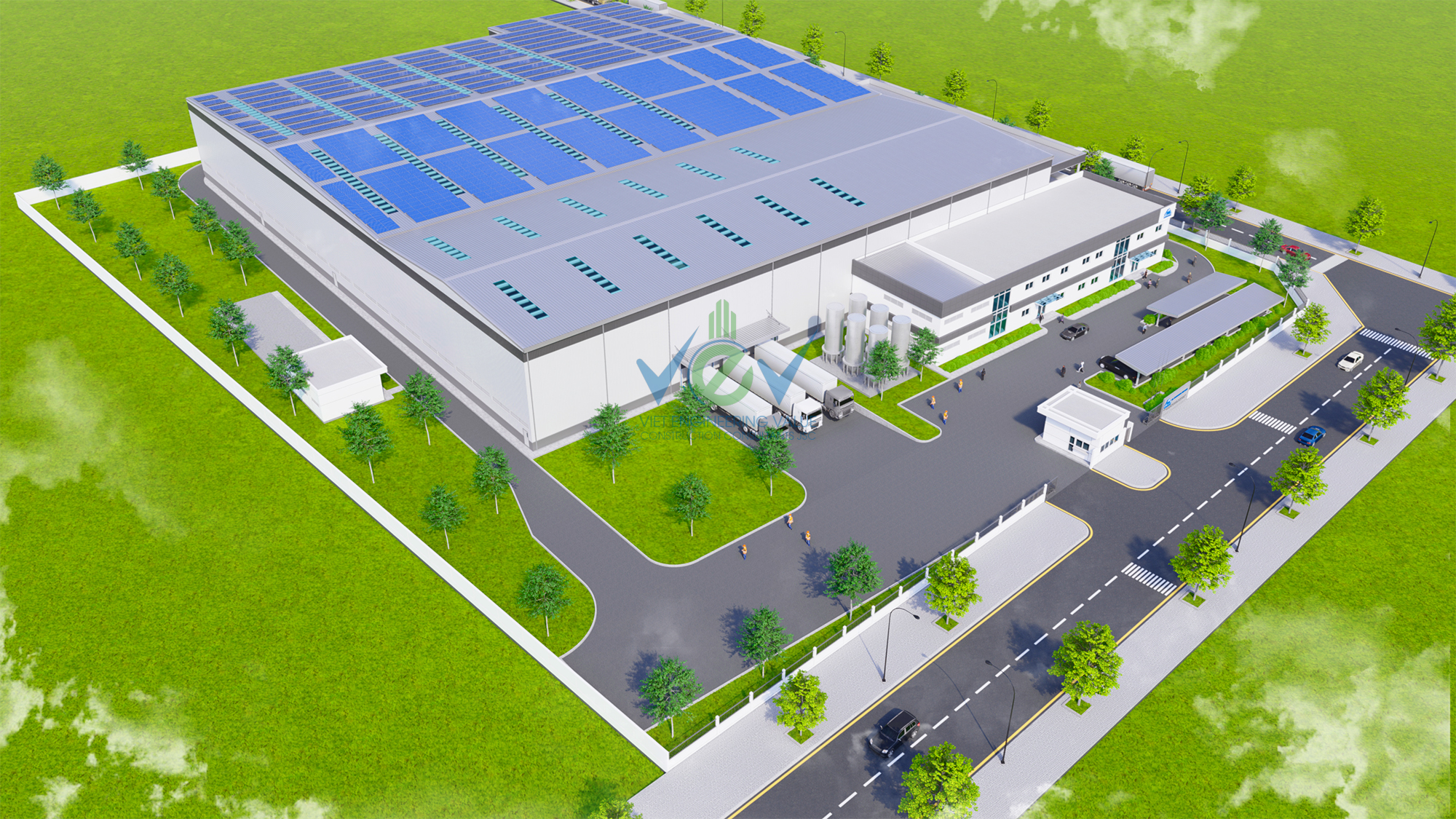

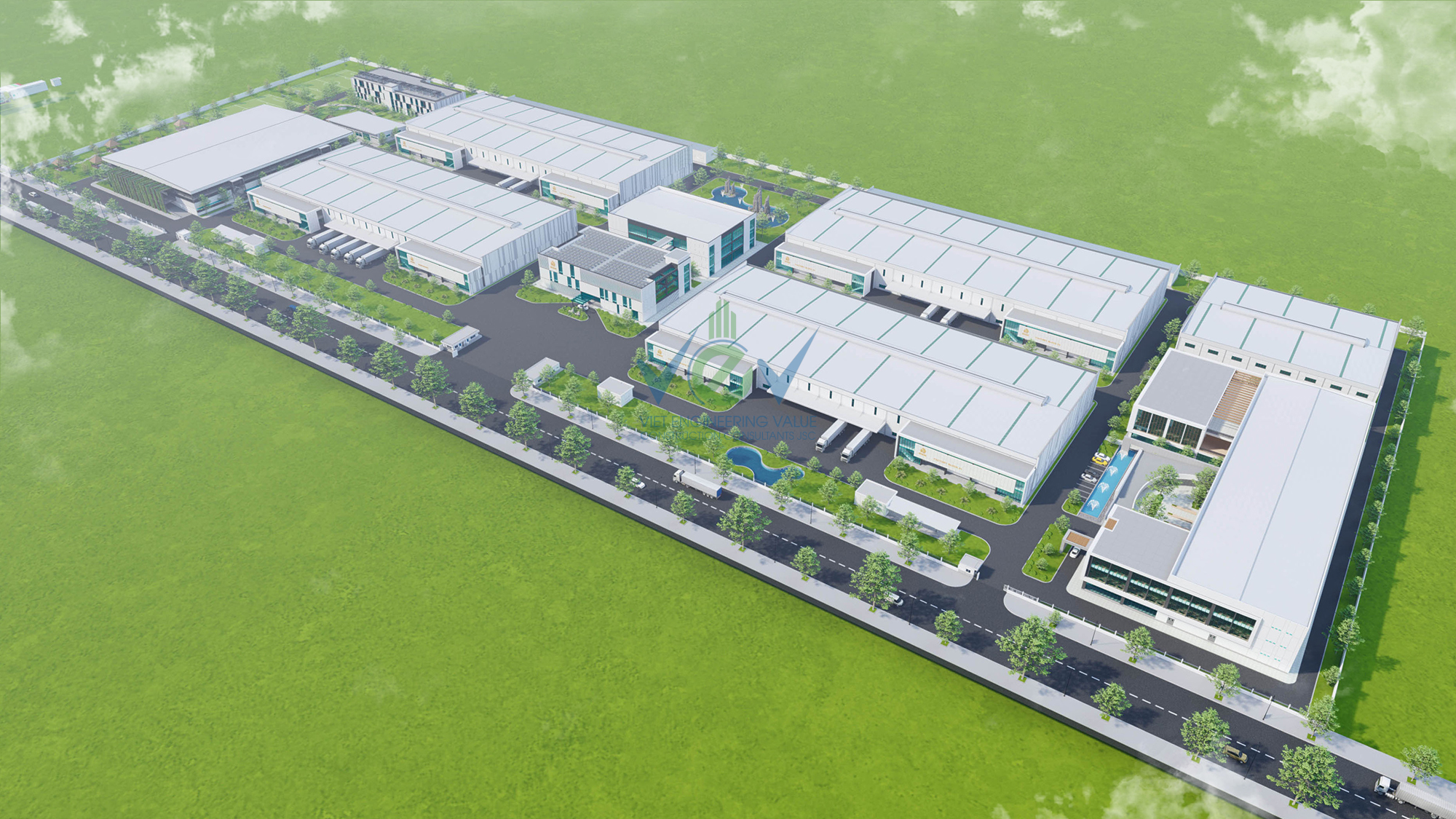

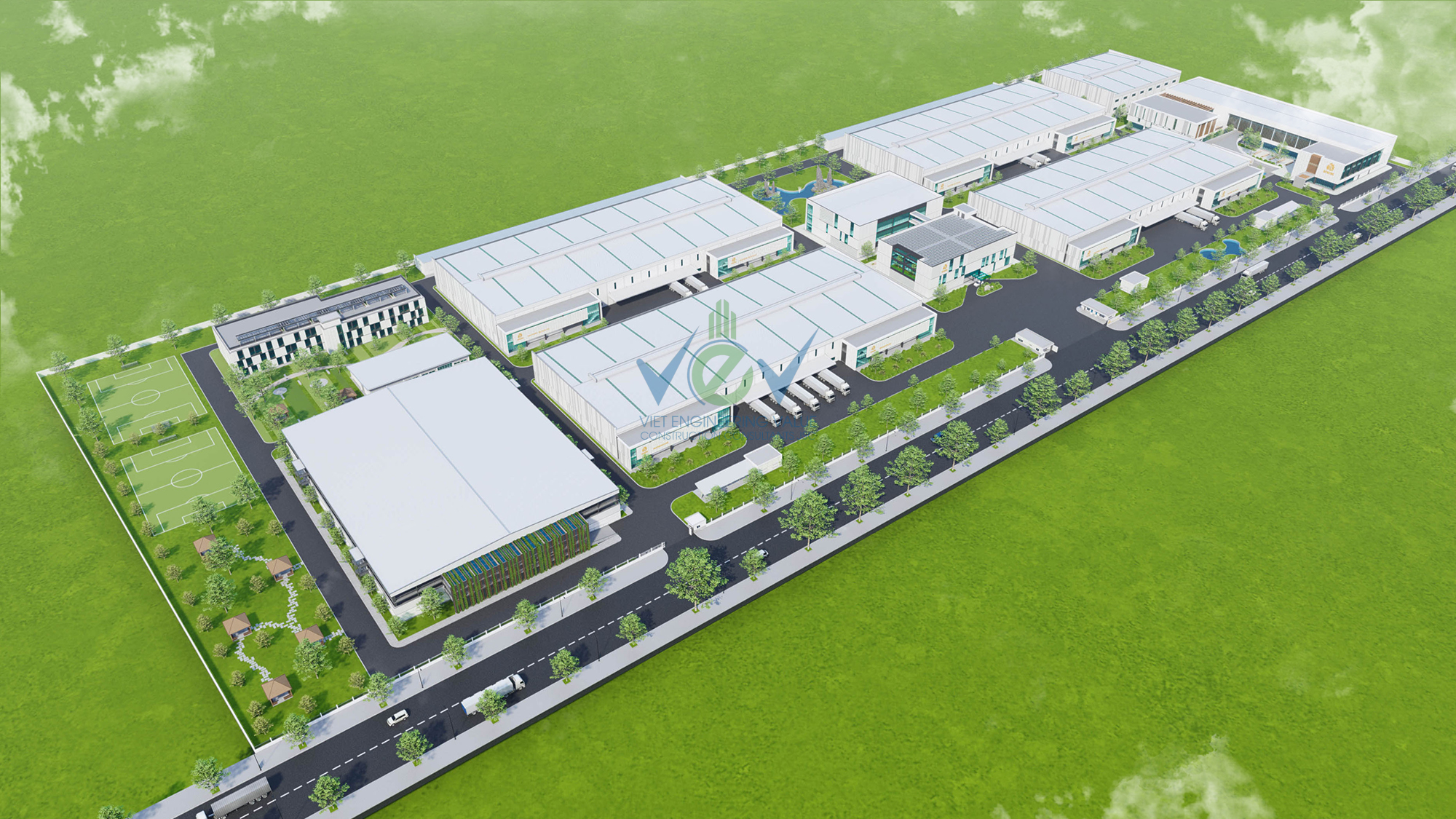

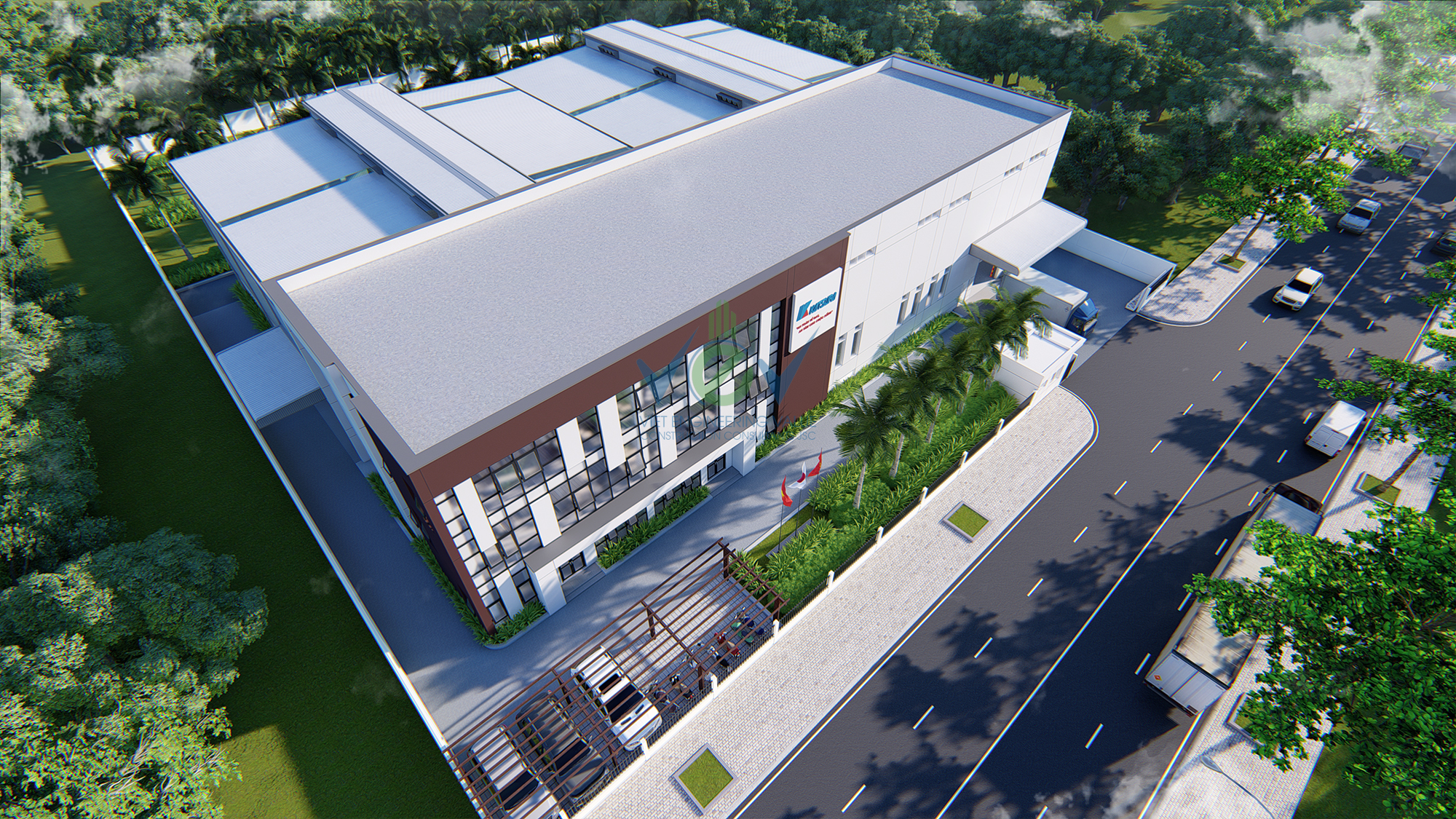

n 11th June 2016, Bluescope Steel celebrated the Gala Dinner to invite the Investors, Contractors and Consultants to honor the Pioneer in Green projects. IN Gala night, VEV Consultants was honored to receive the award with the Design of DBW Garment Factory. The Design of DBW factory had won in comparison with other Designs to lead one Industrial design in Vietnam getting double Platinum Certification, one is Leed Platinum Cert from US Green Building Council, and the latter is LOTUS Platinum Cert from Vietnam Green Building Council. Together with specific building shading shape, the Design of DBW had applied a series of innovated material and technology, such as insulated Low-E glazing, the thermal insulated building envelope, the HDPE drainboard for roof garden, the solar battery panel, textile ducting, the recycled gray water and rain water system, water-saving fixtures, drip irrigation and most recycled density material. The Design of DBW has proved the Design Qualification of Vietnamese Architects and Engineers can compete with forein expats in creating the high-class product in Sustainable and Energy-Saving Design. Platinum is the highest certification level in International Green Cert System.

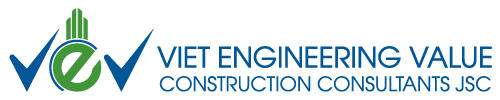

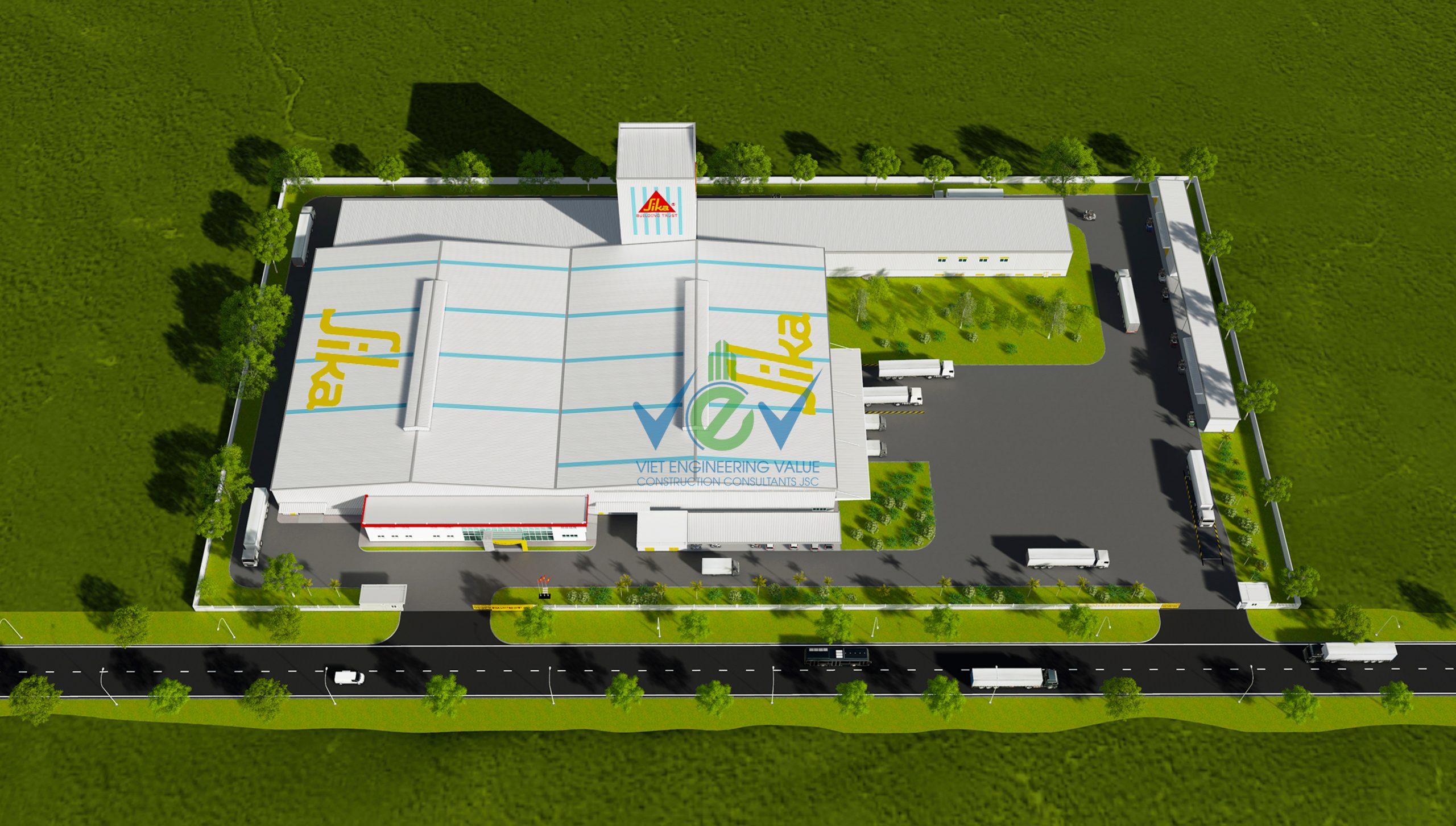

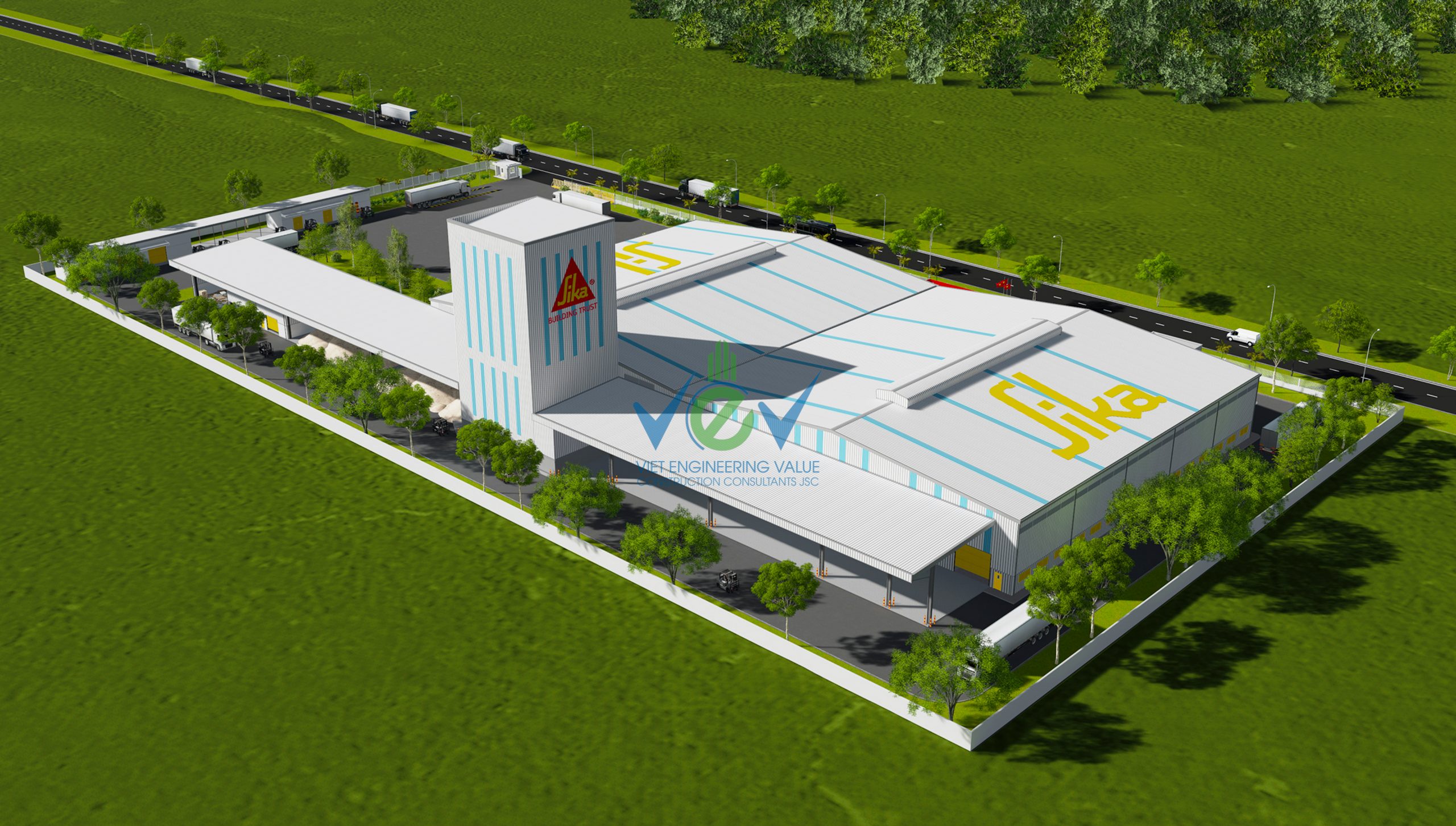

Some images in Gala Dinner:

hai công trình được vinh danh, trong đó có công trình Nhà máy may mặc Đức DBW

Mr Vo Minh Nhut, President of Bluescope Steel gave flowers and regconition award to Mr Pham Hong Thai, Technical Director of VEV

Recognition

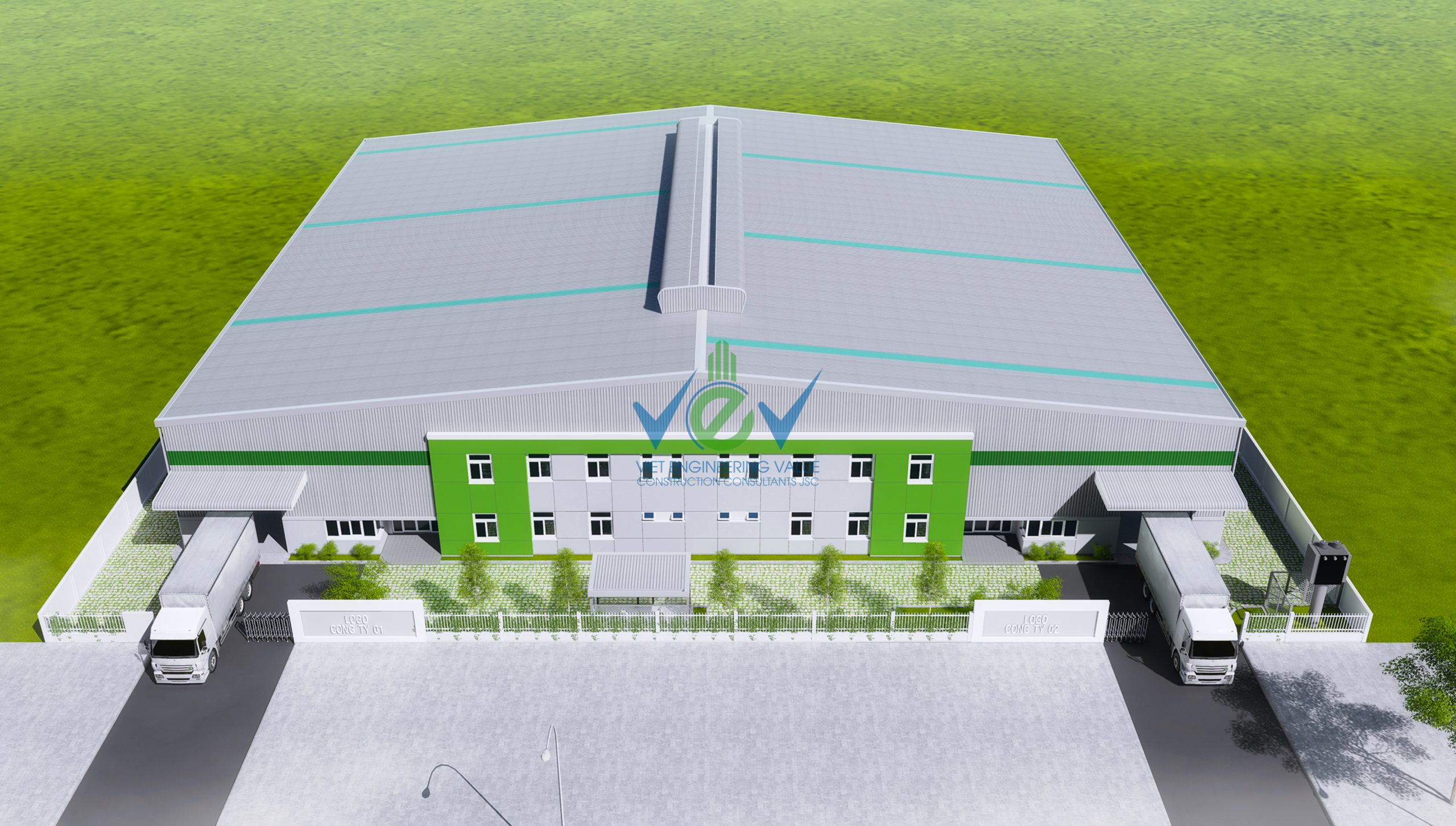

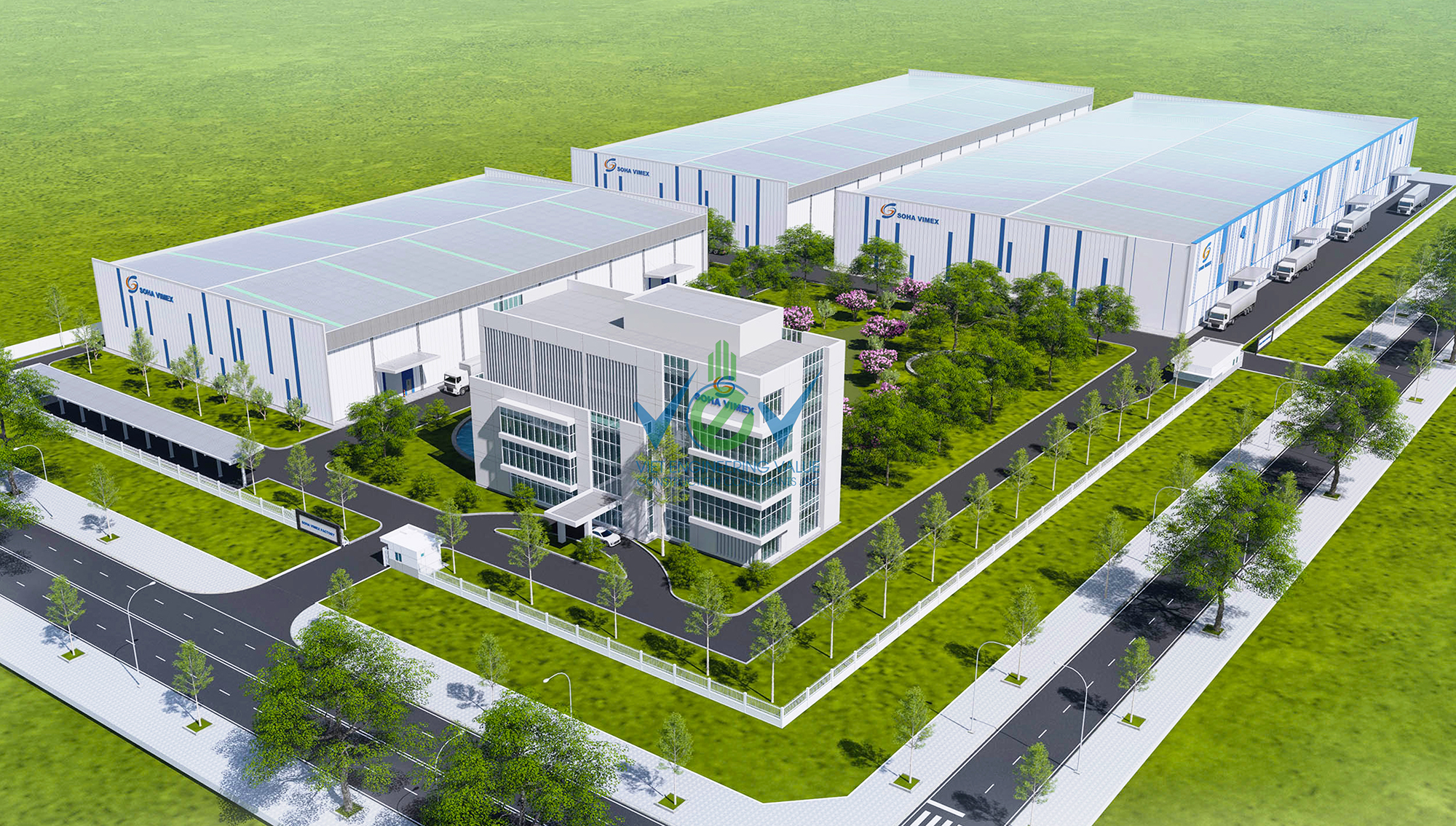

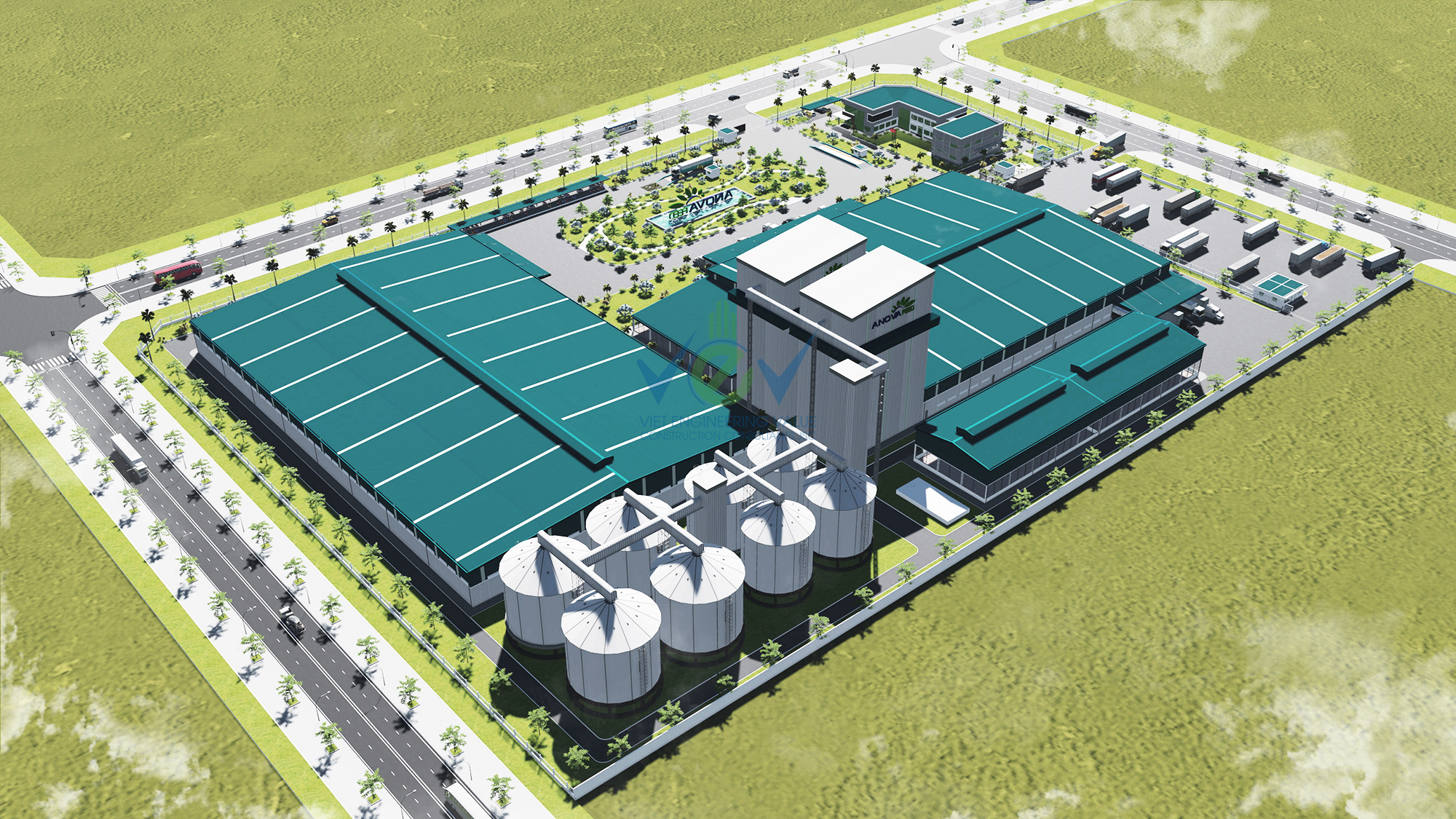

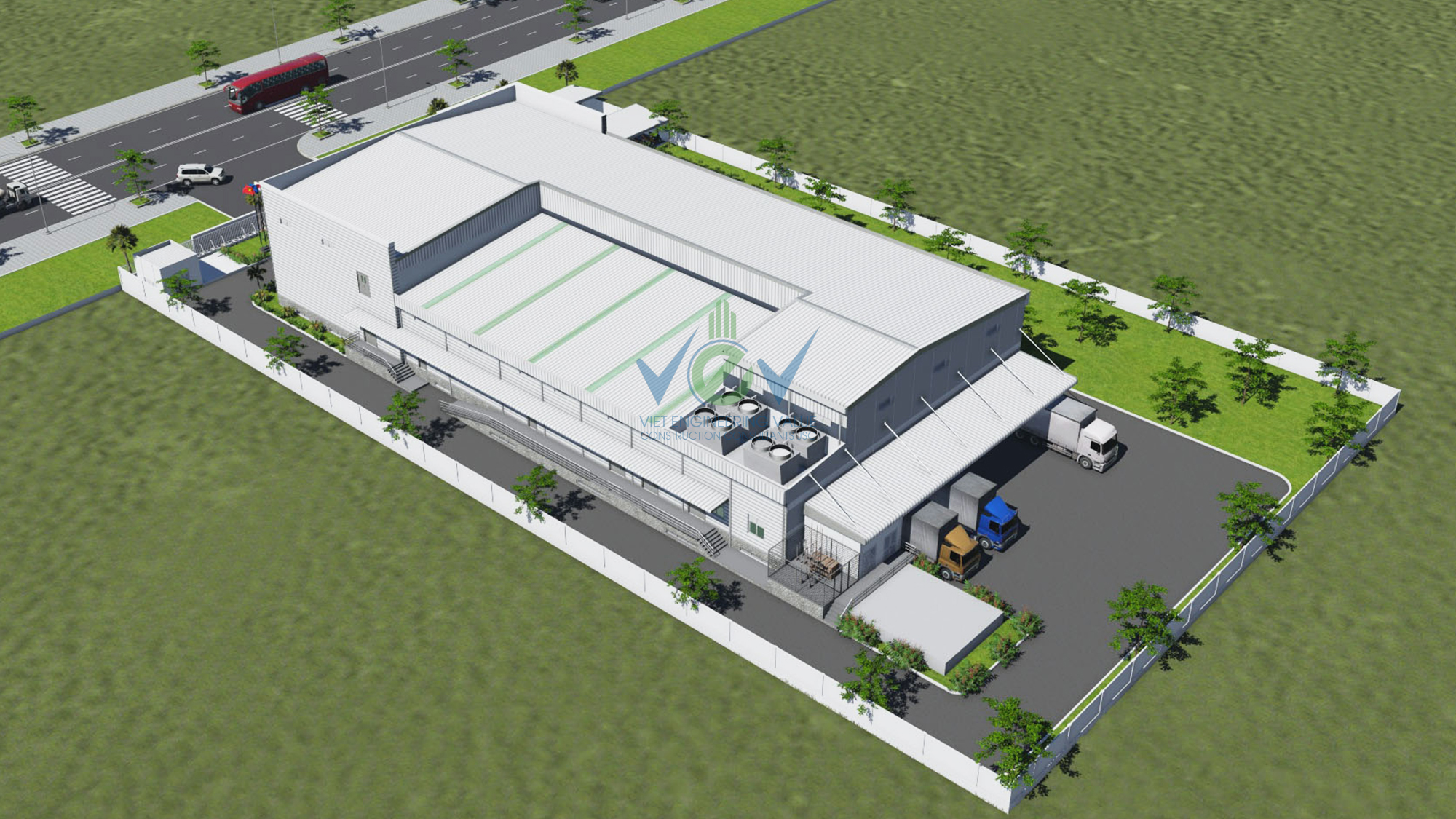

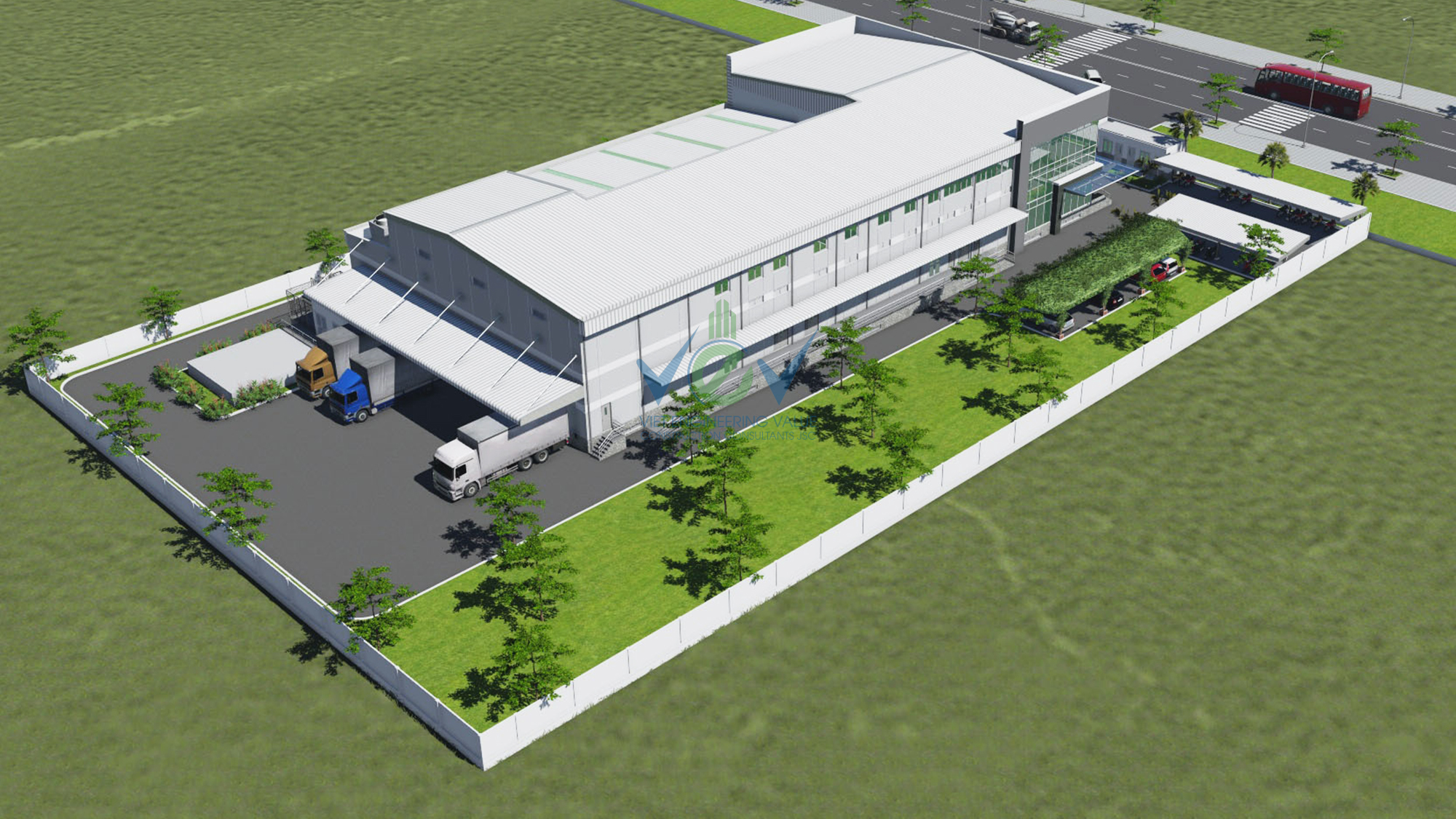

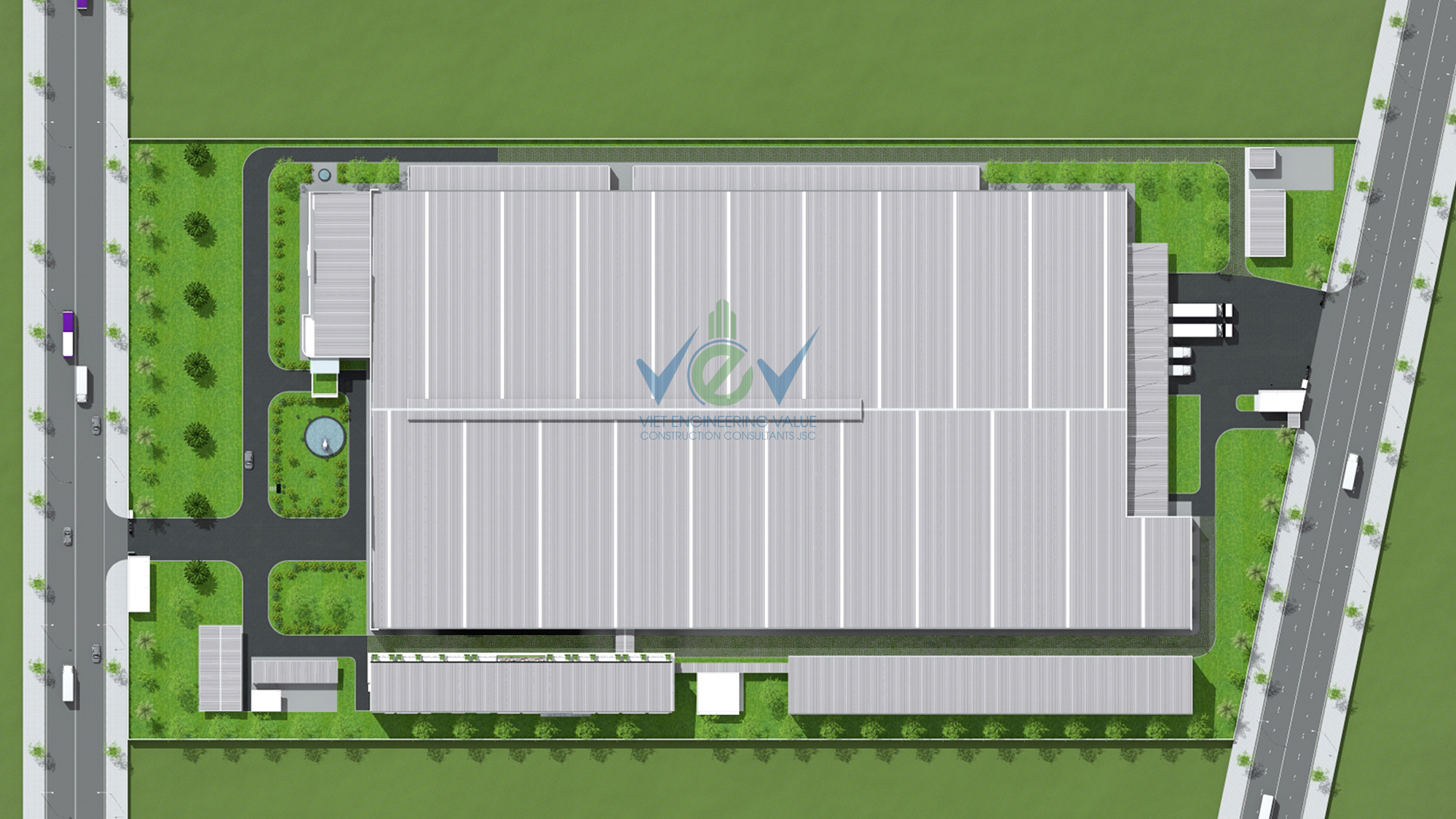

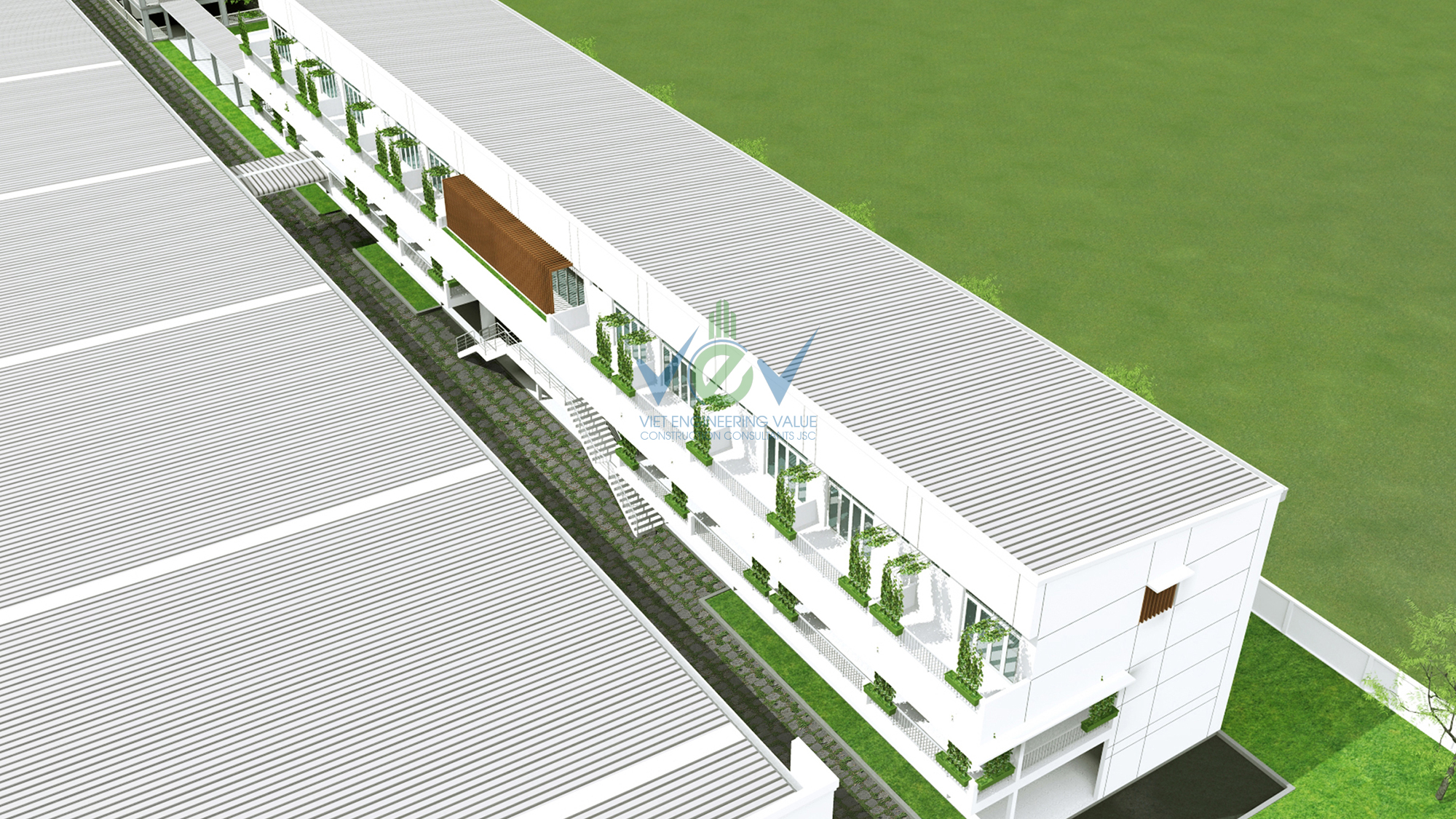

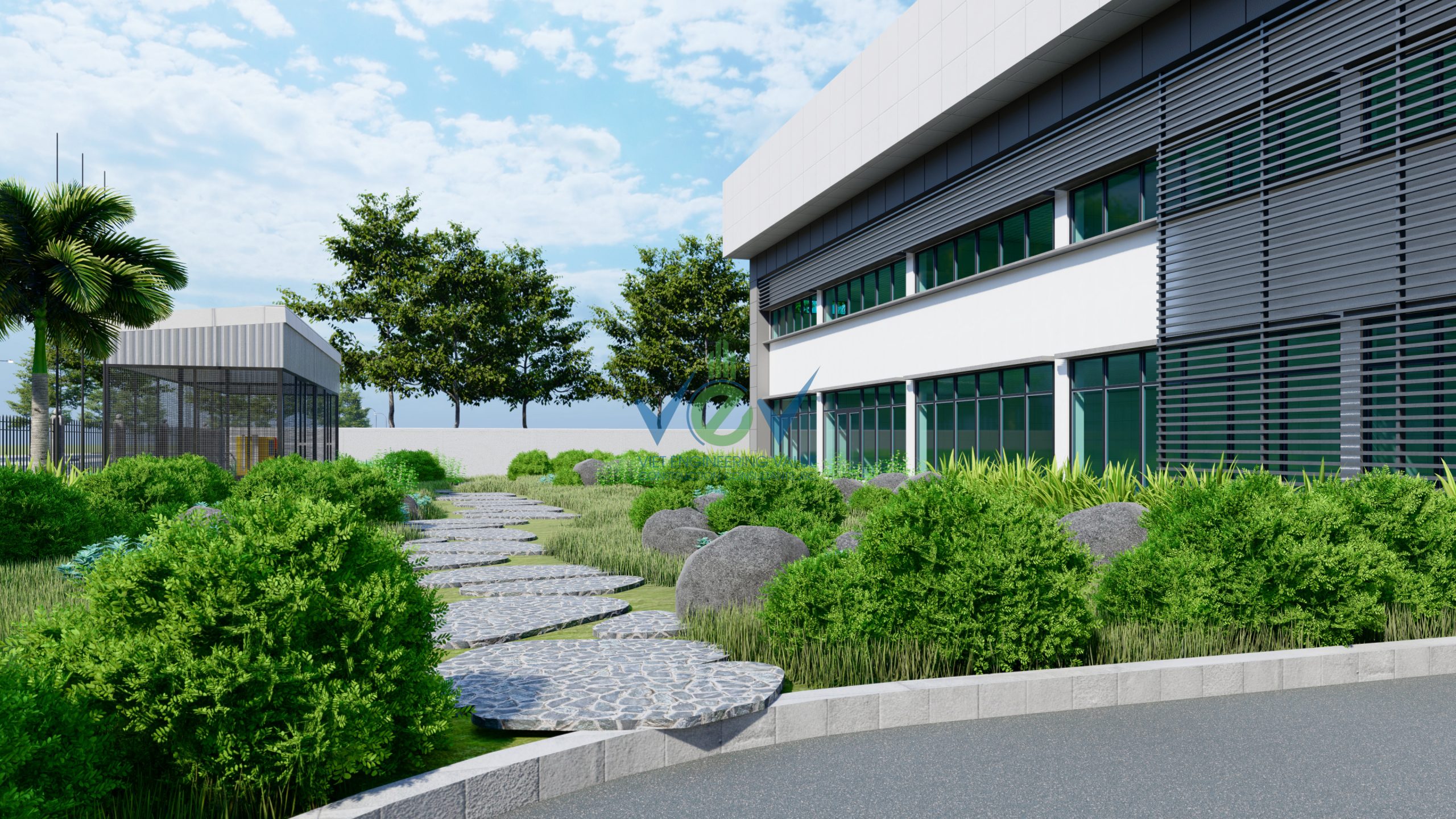

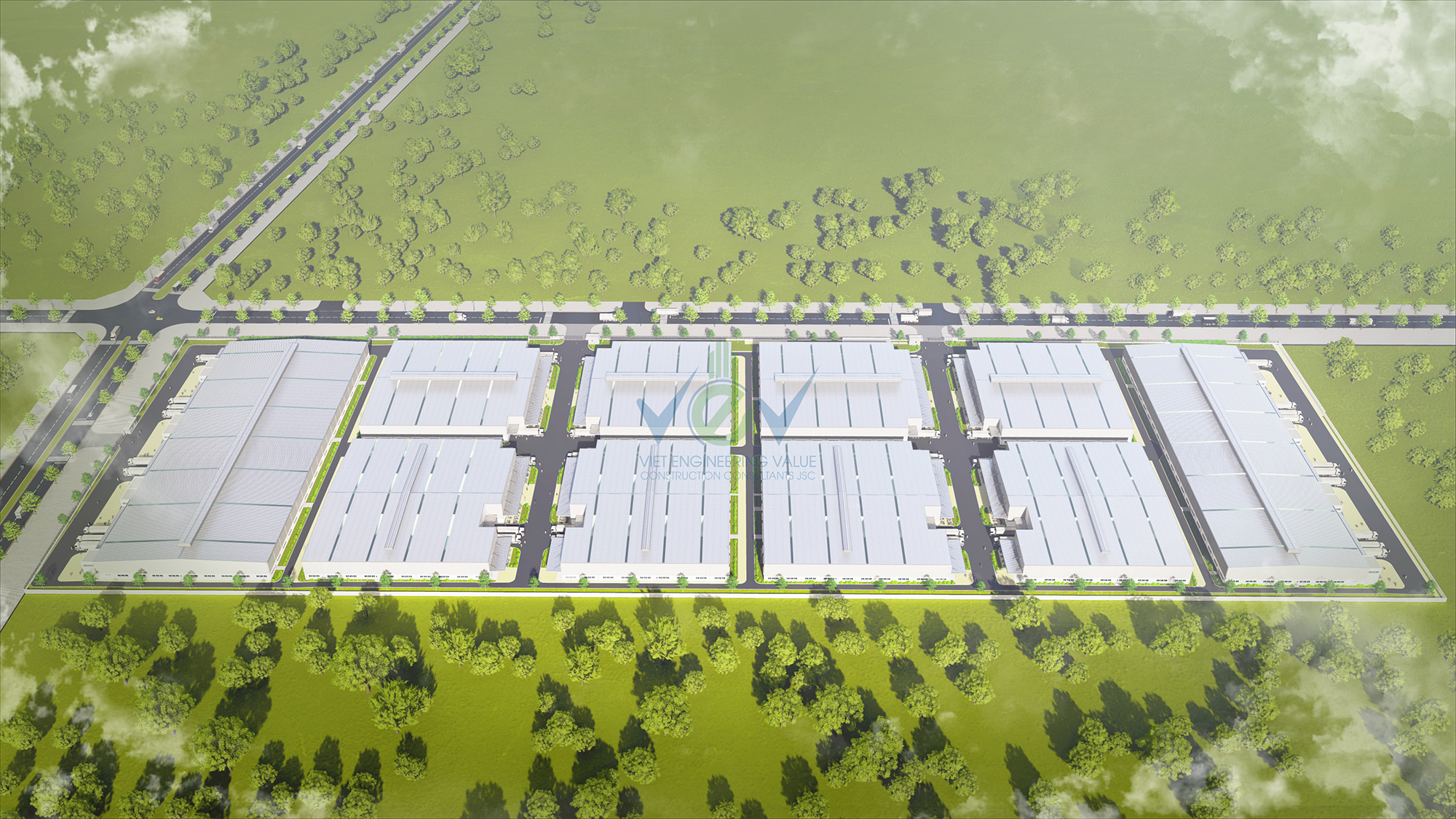

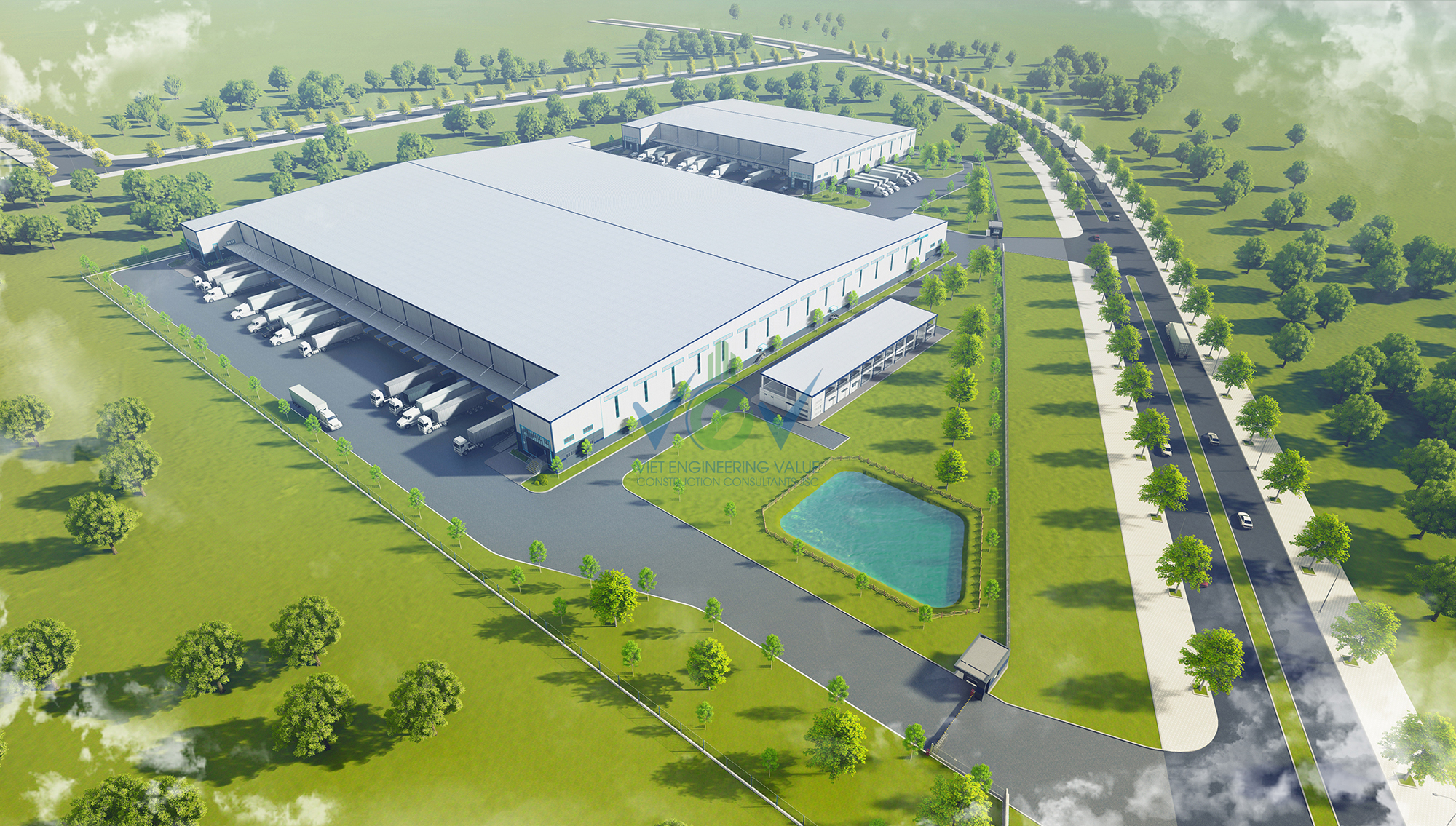

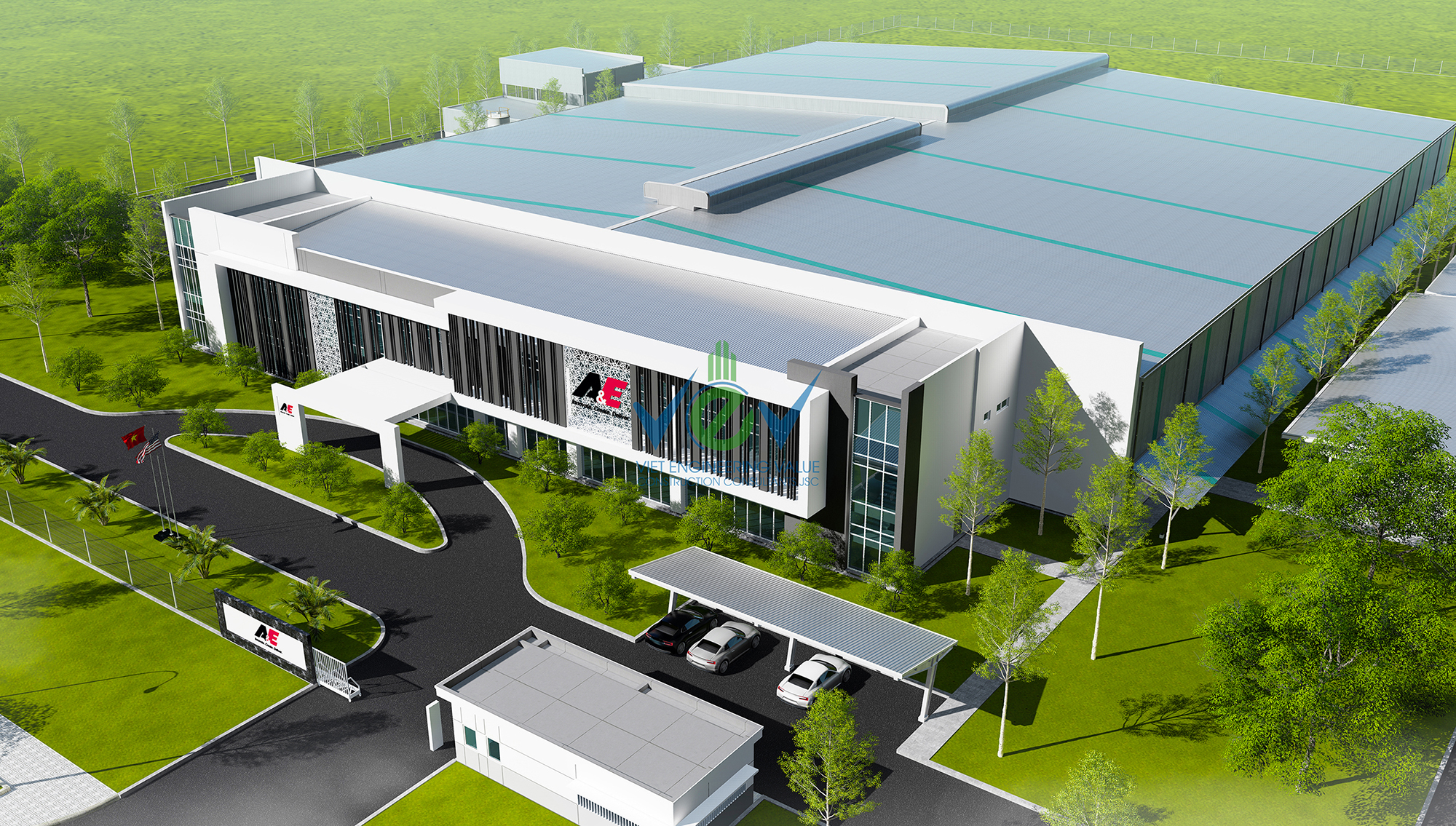

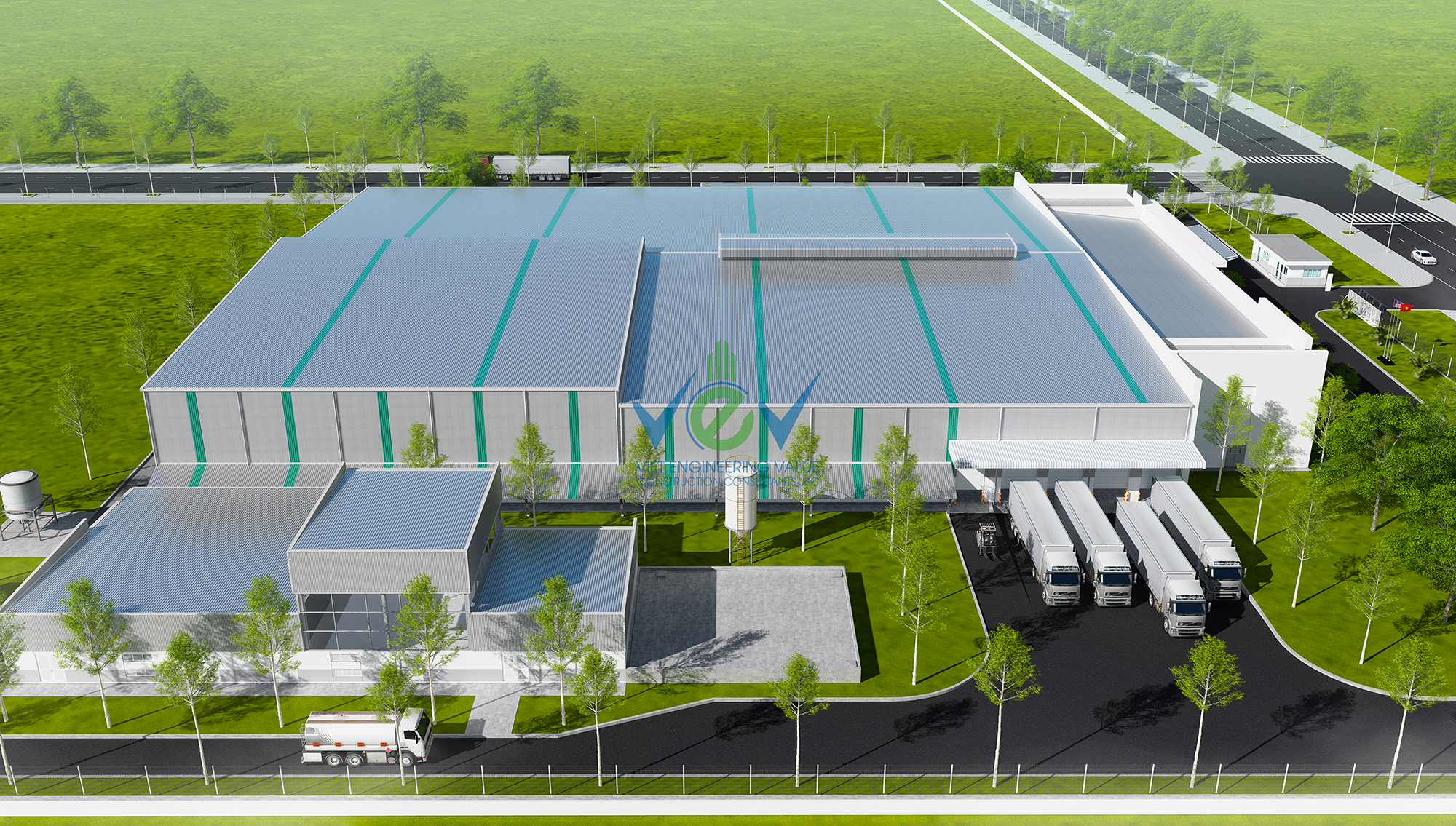

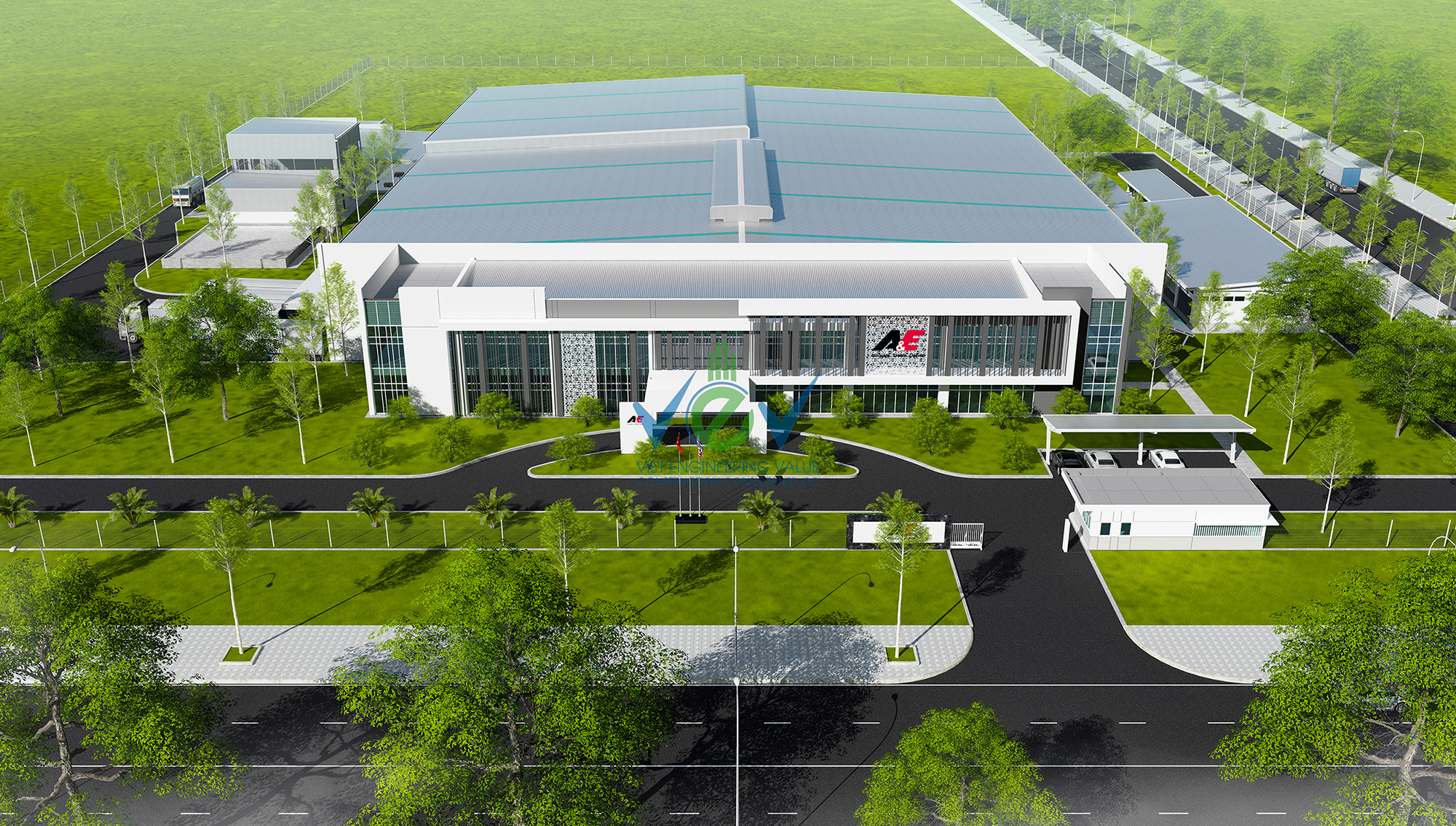

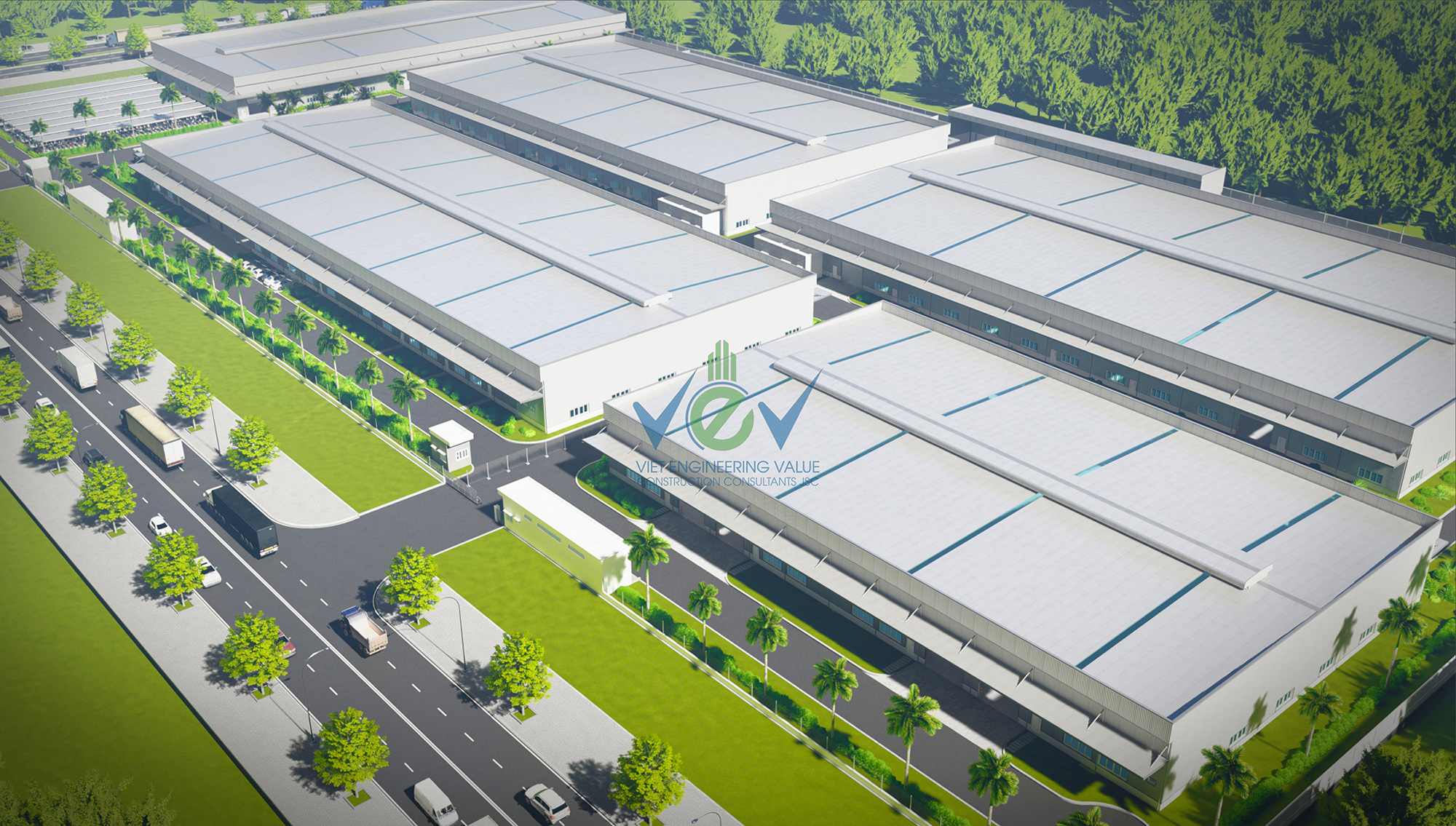

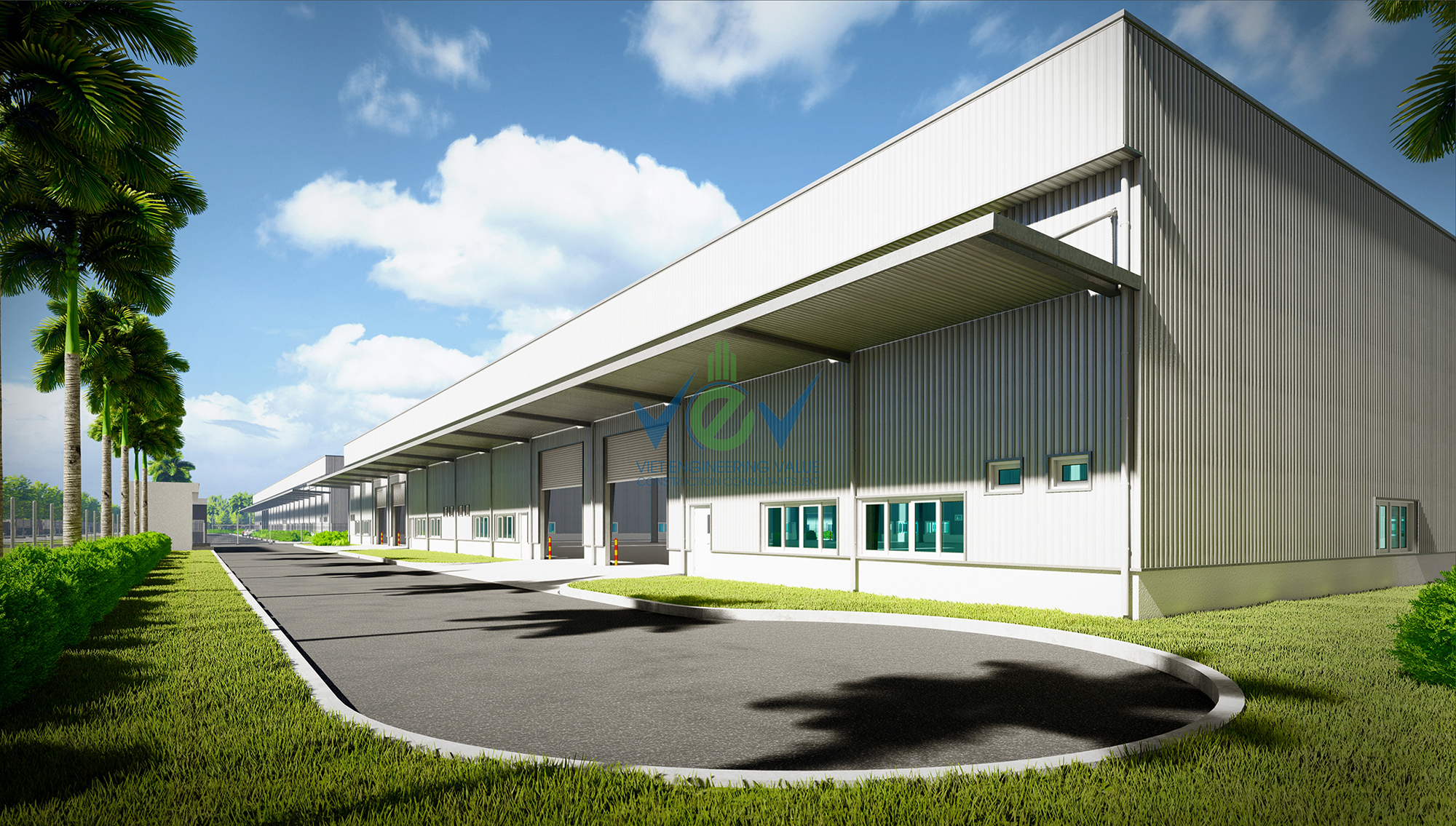

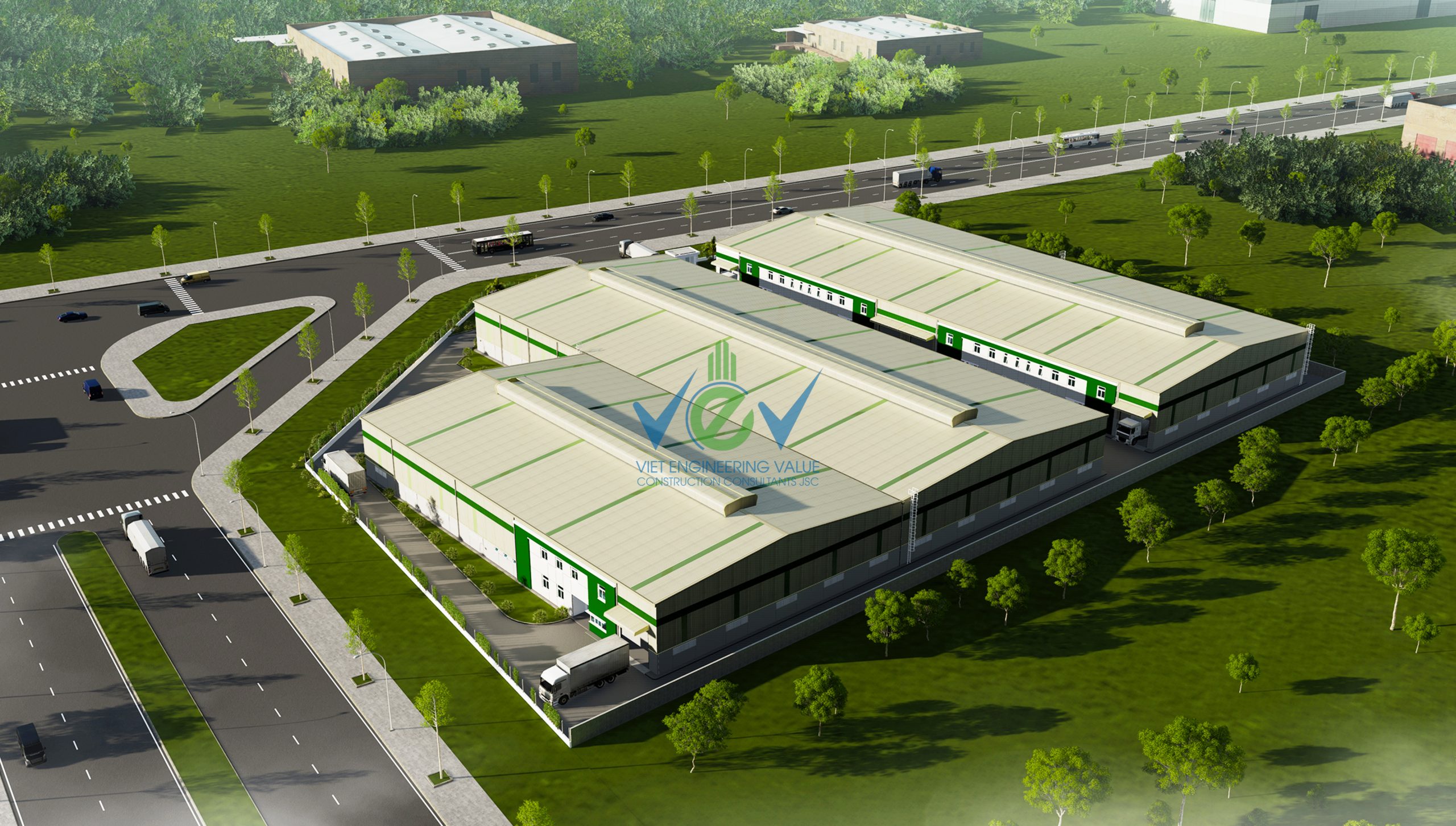

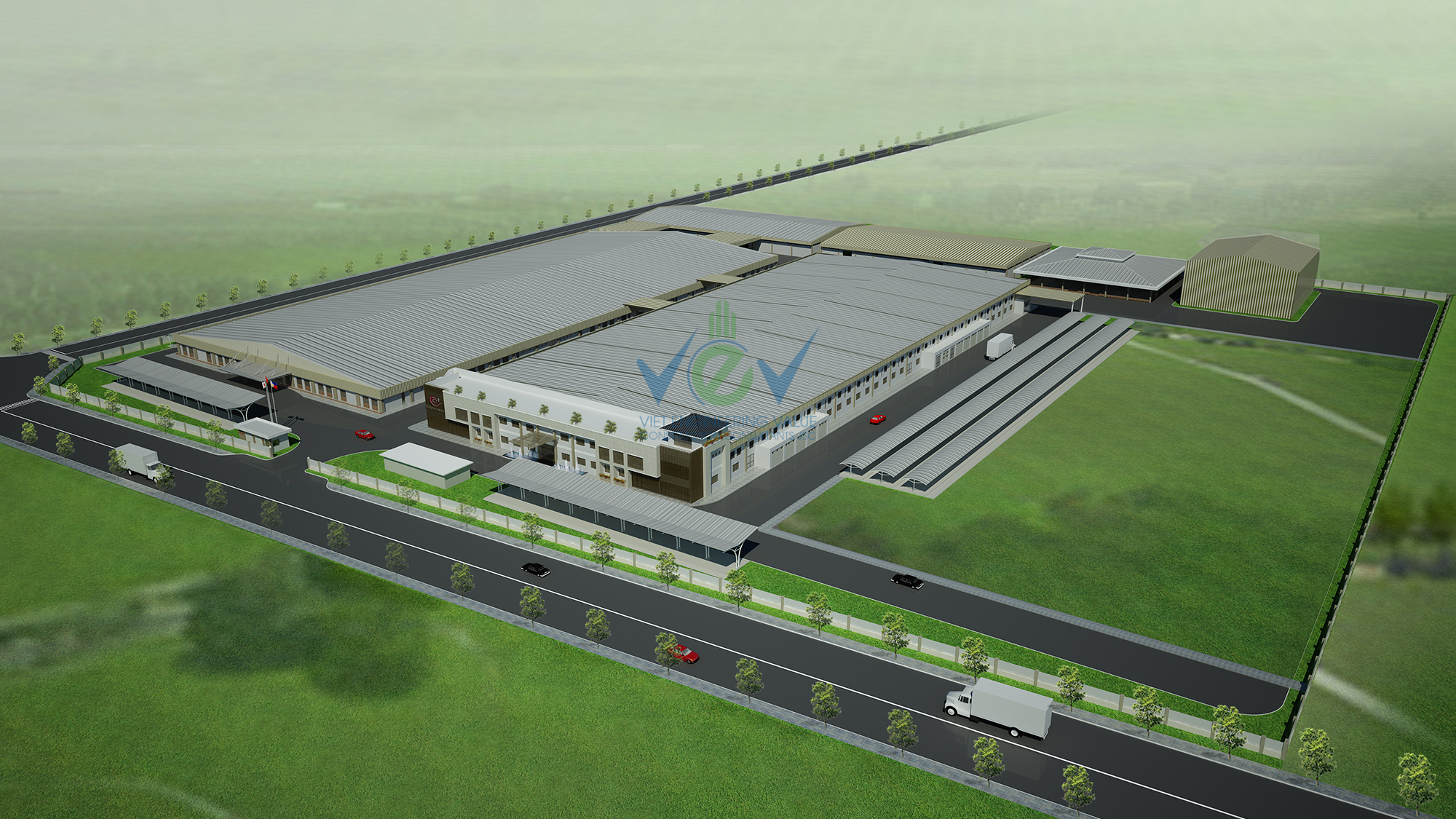

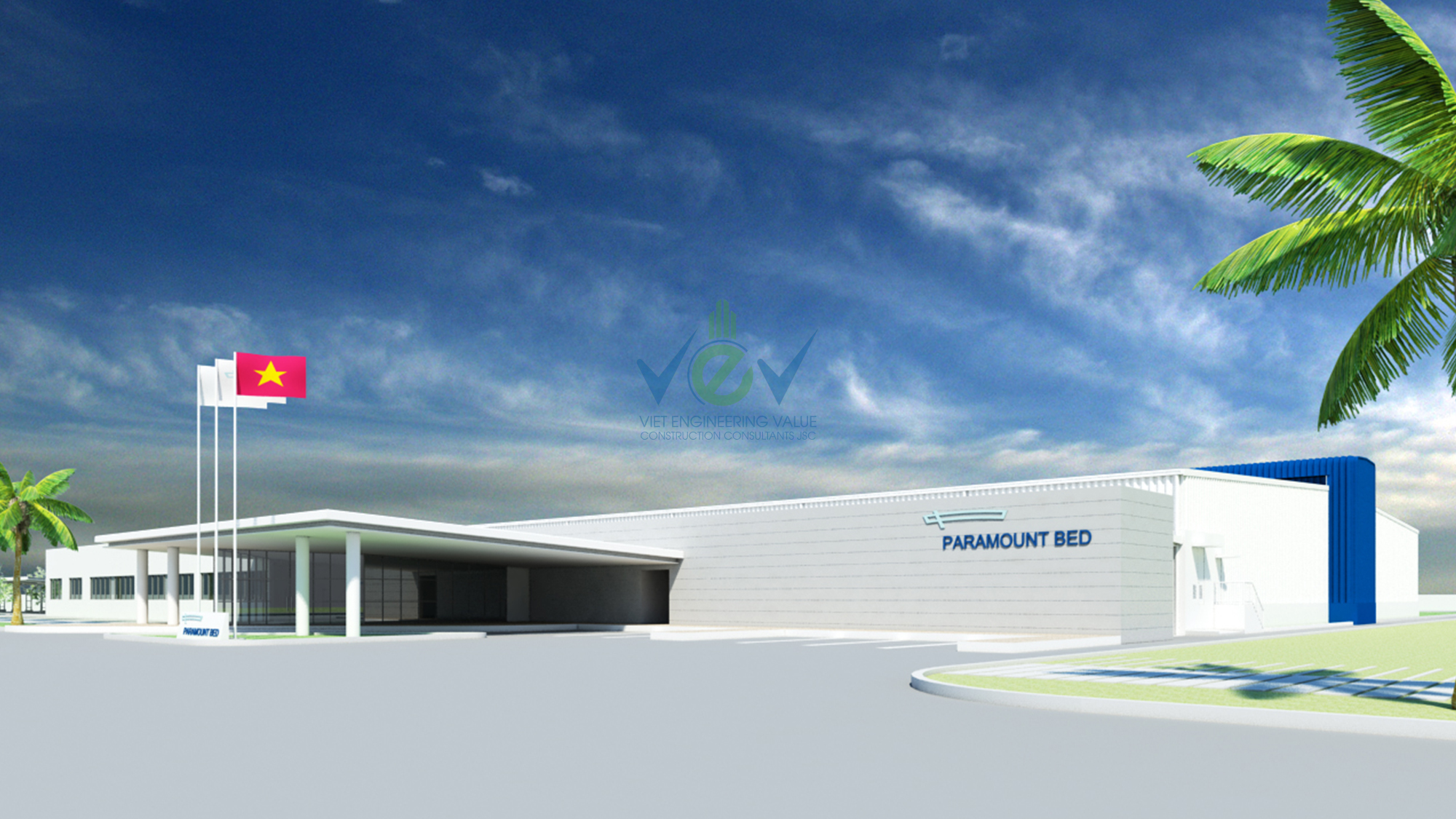

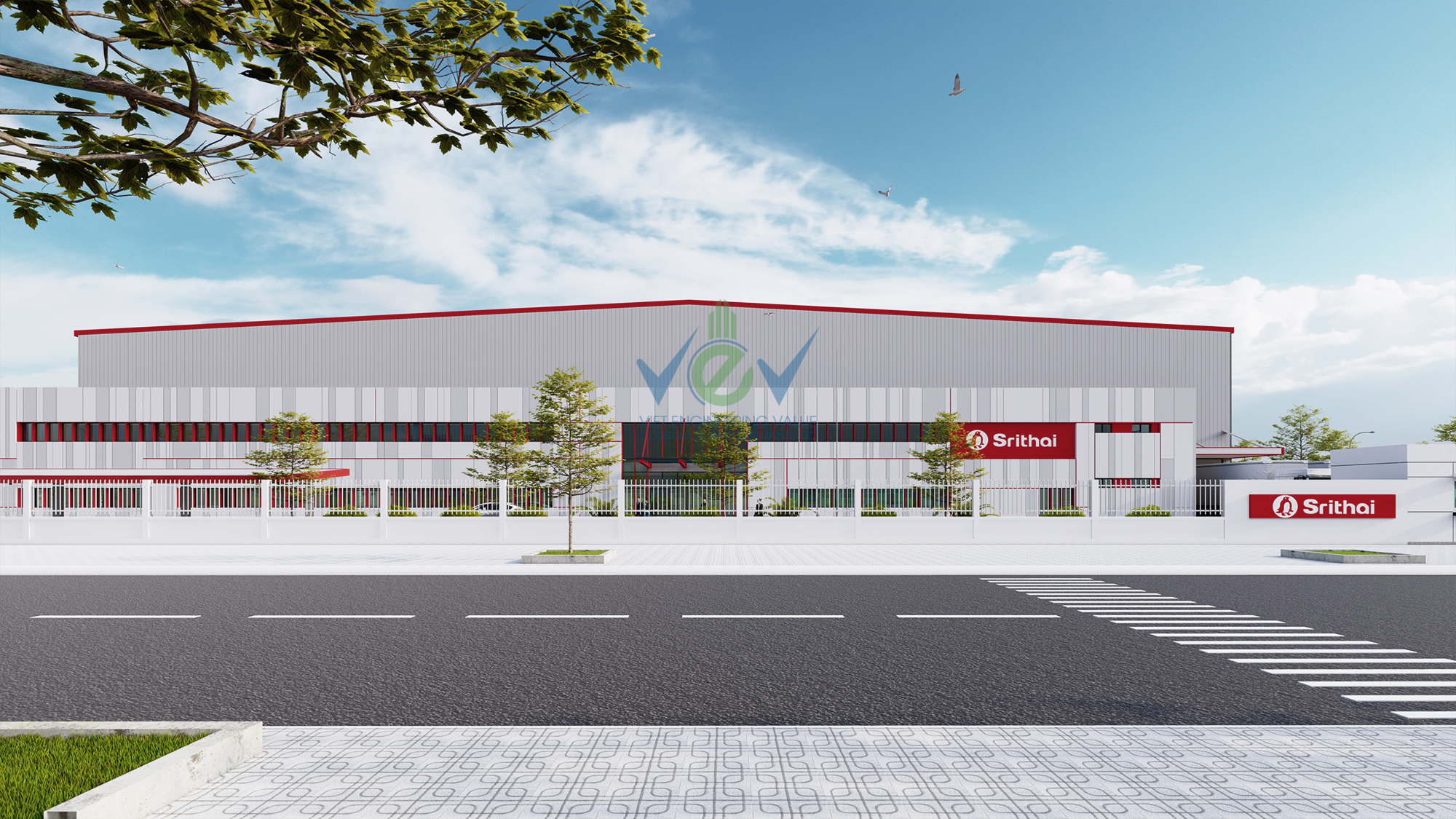

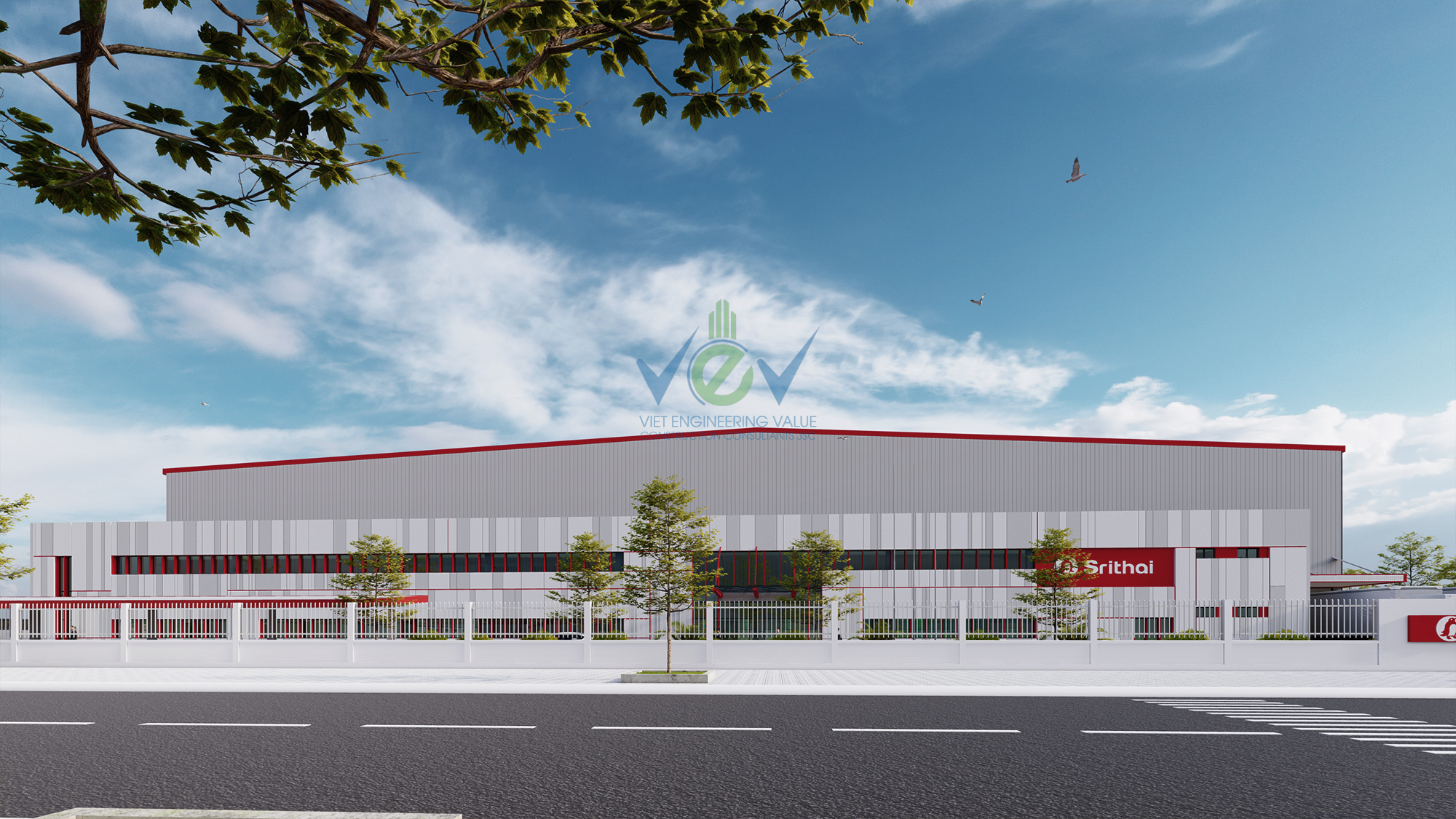

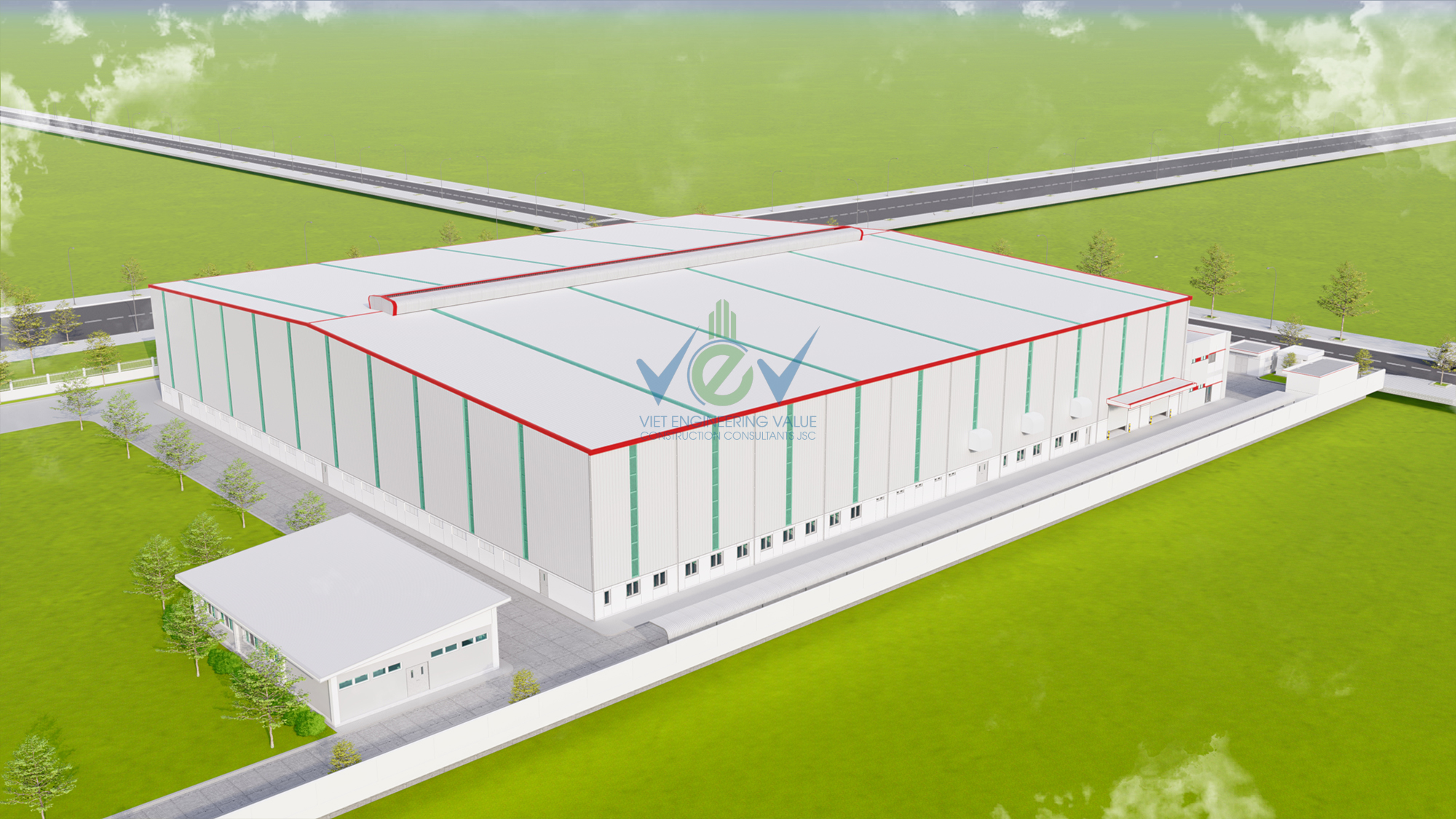

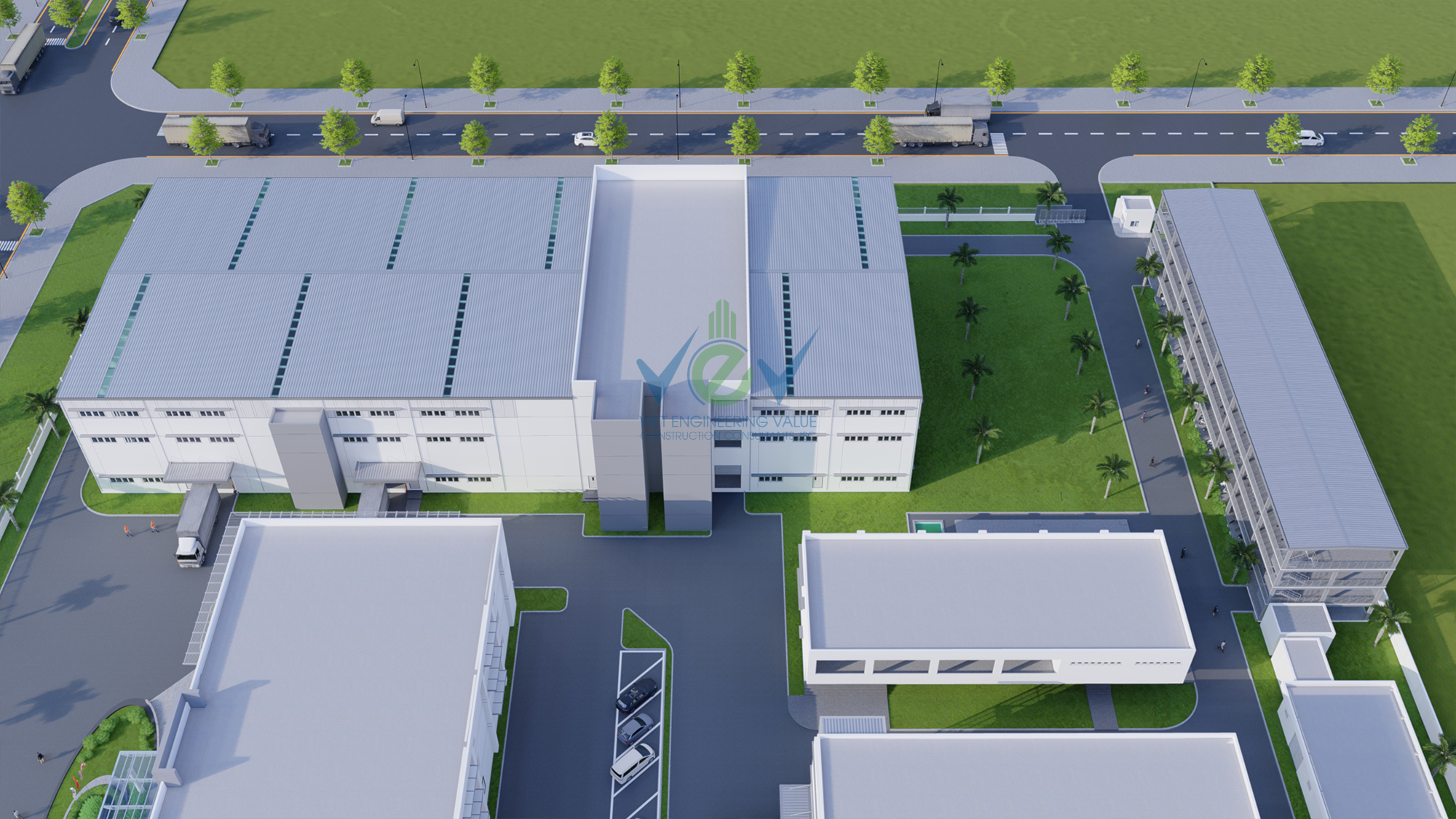

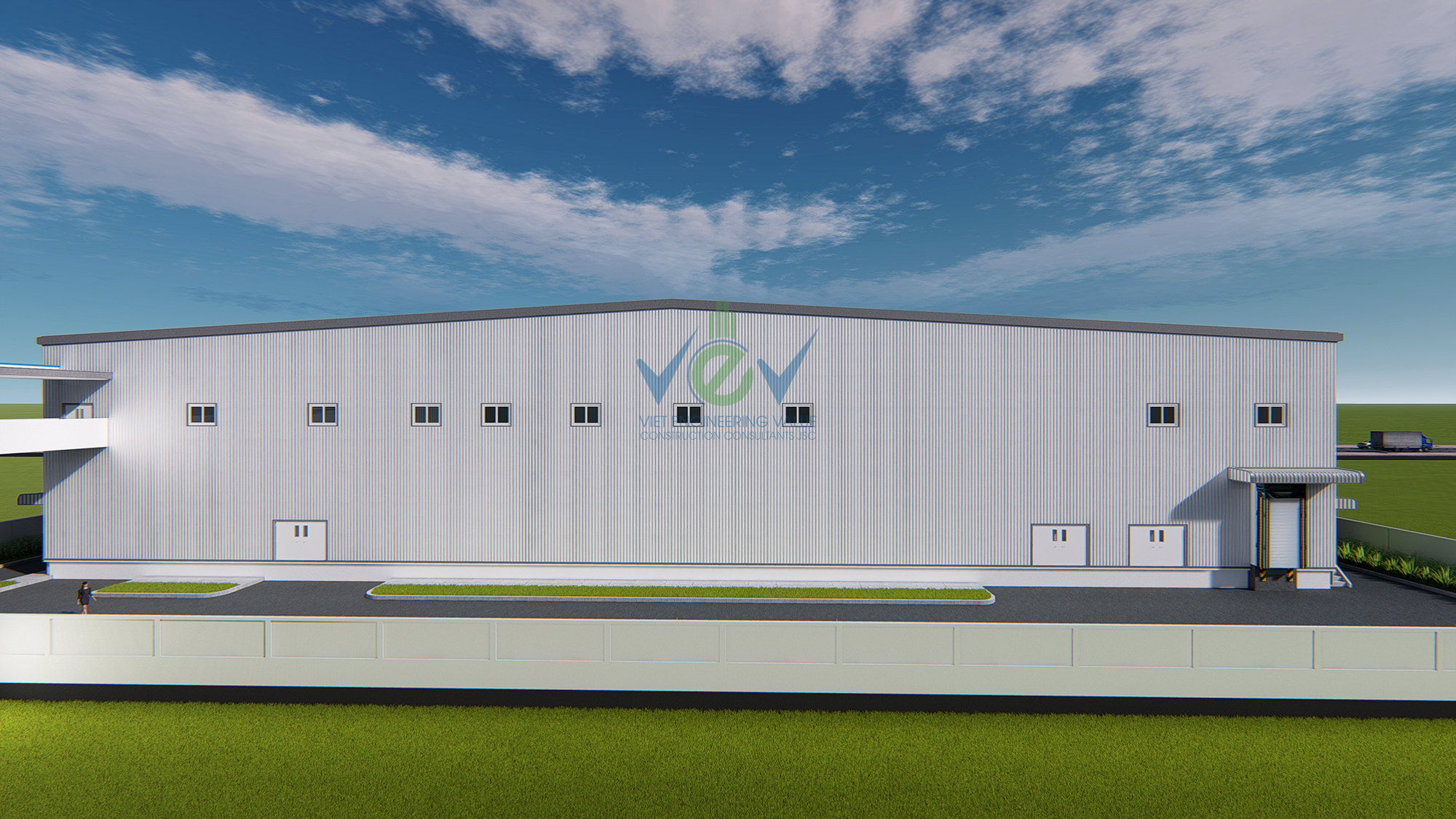

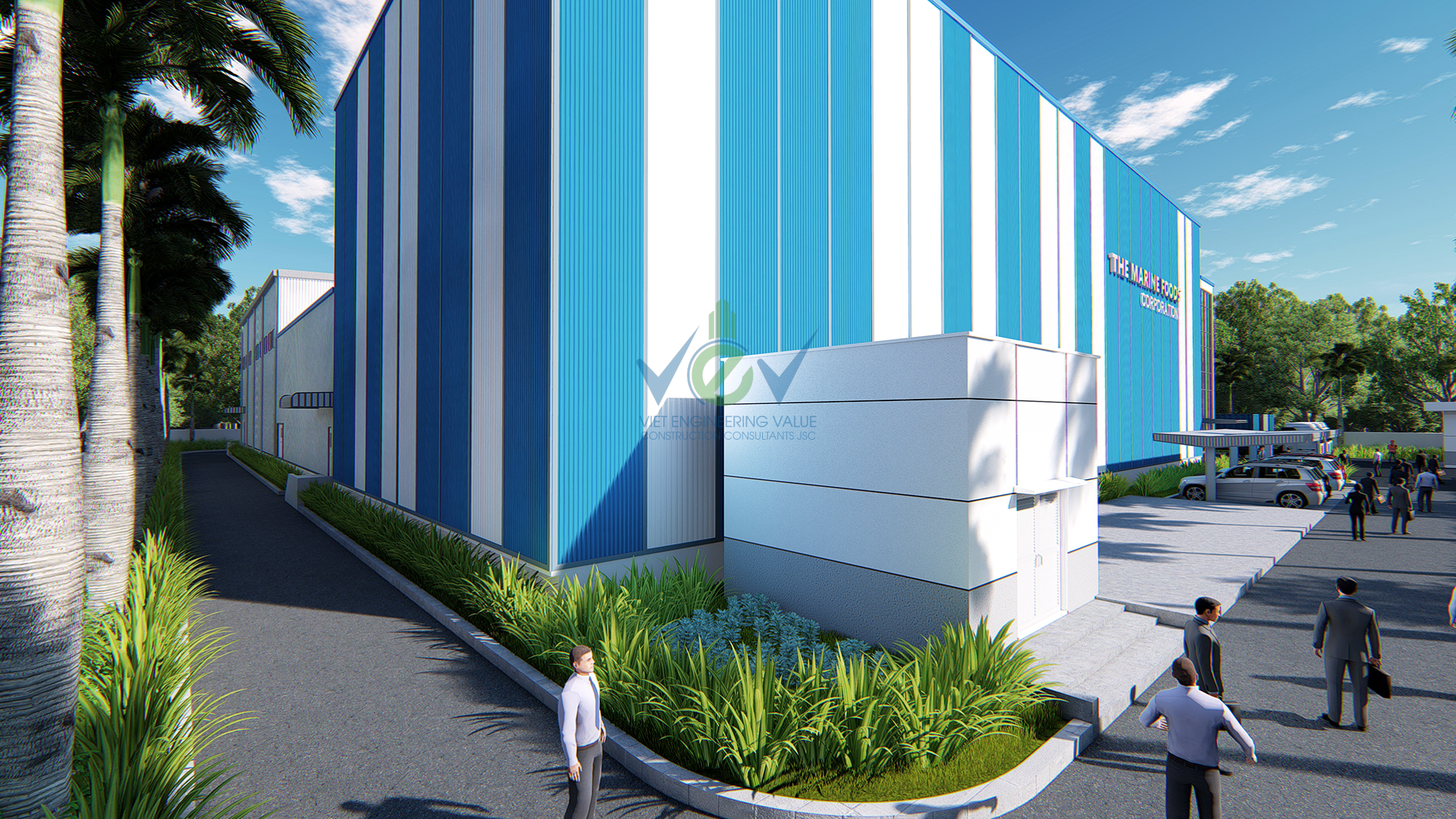

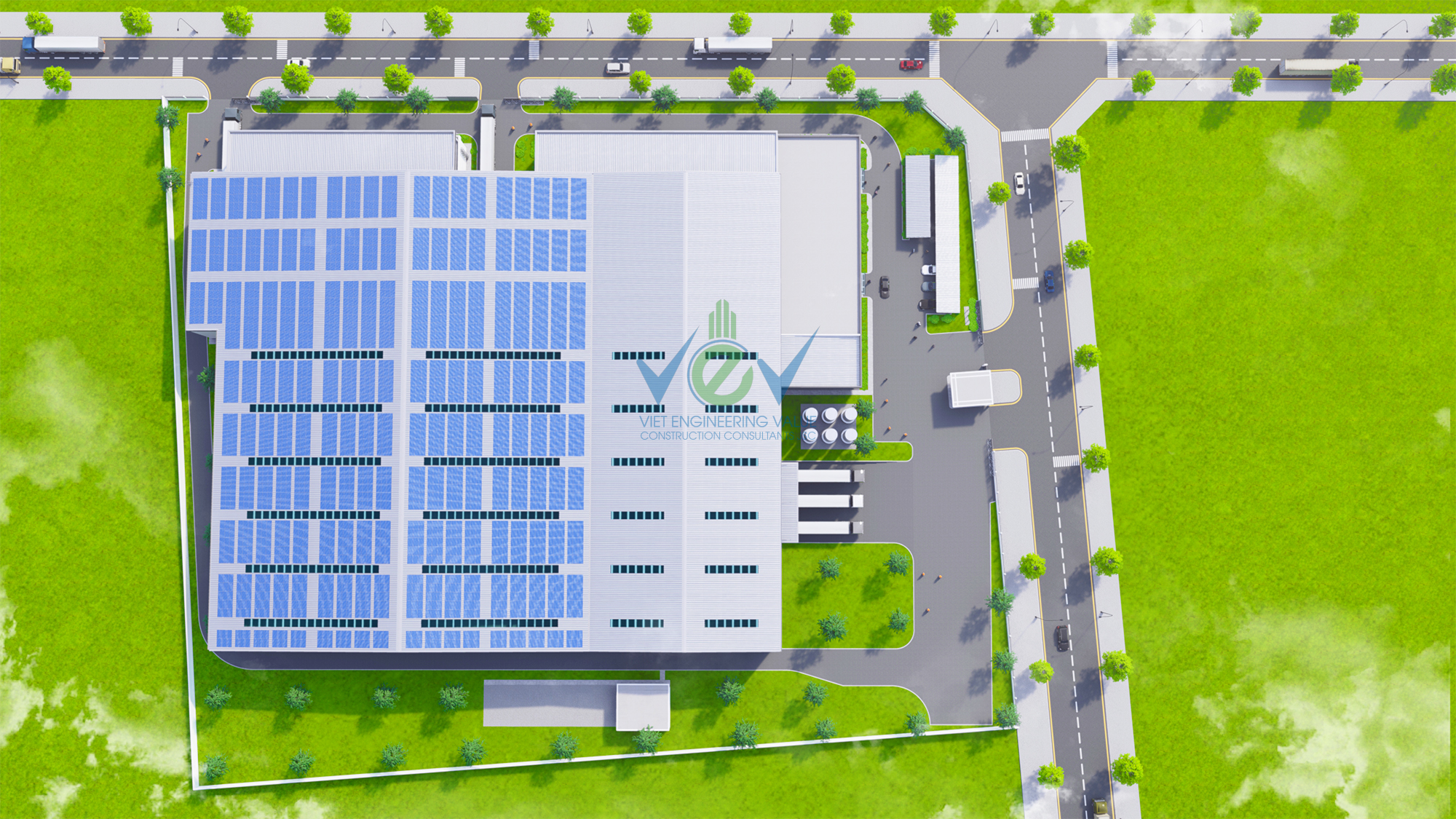

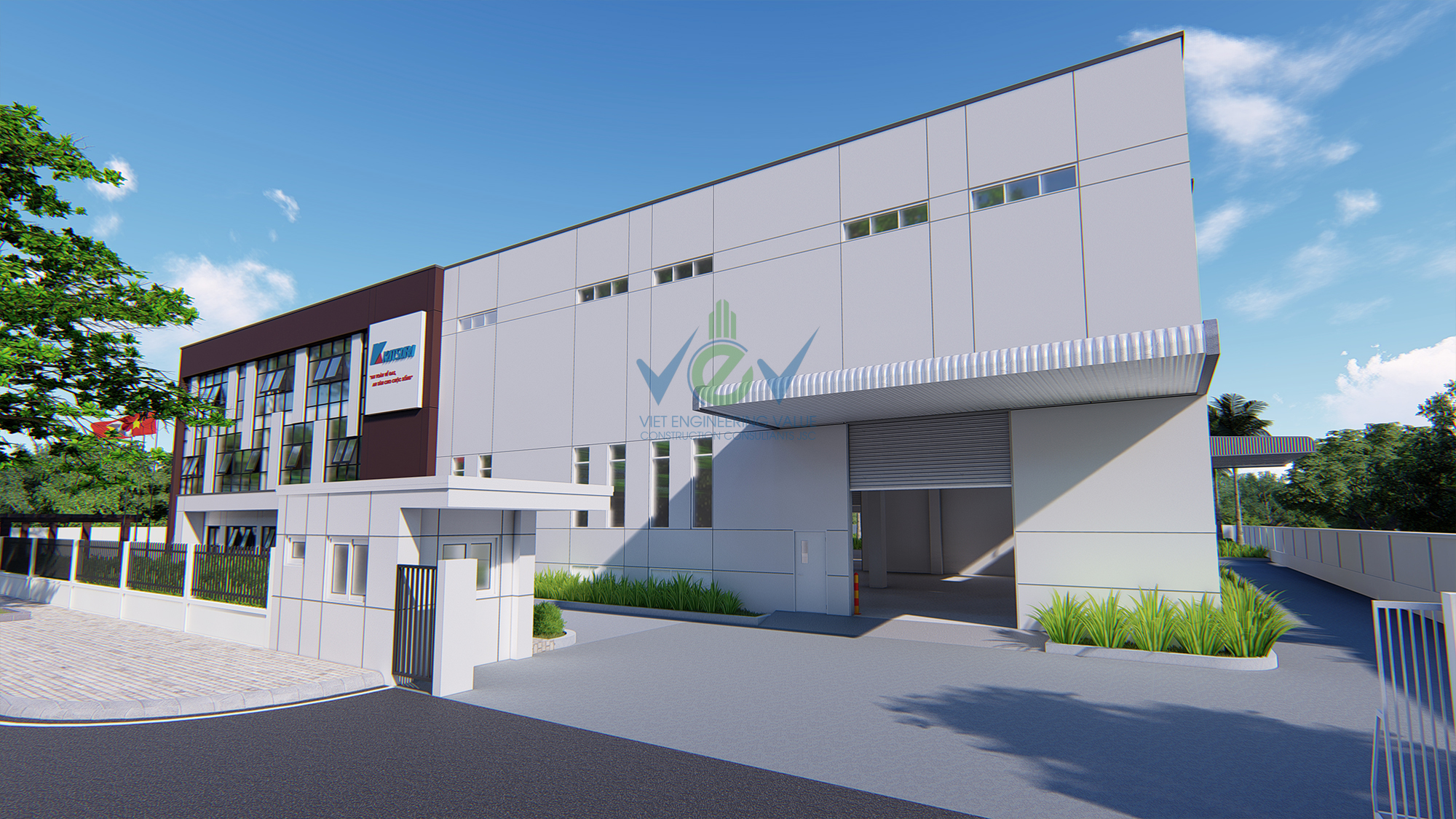

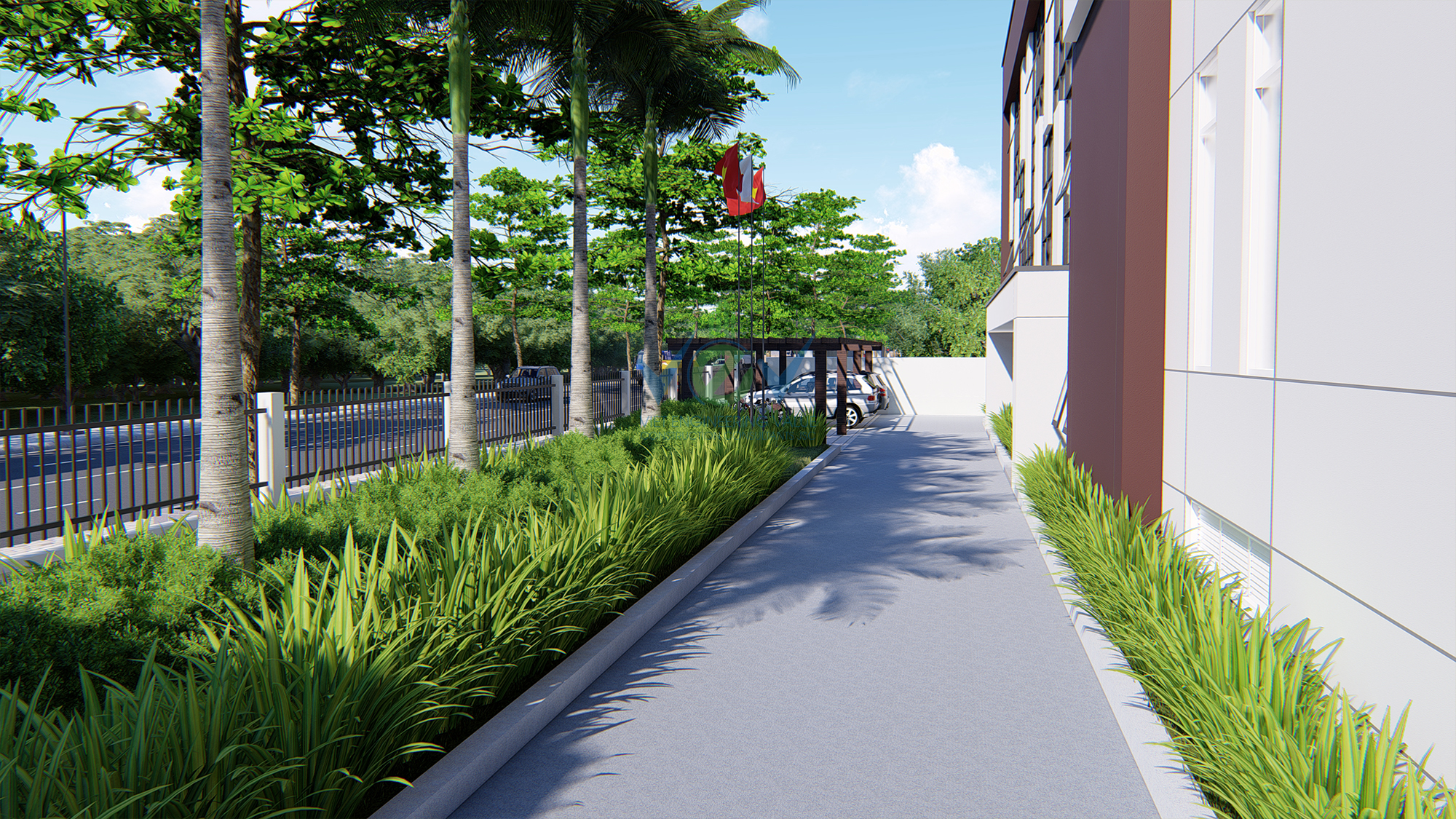

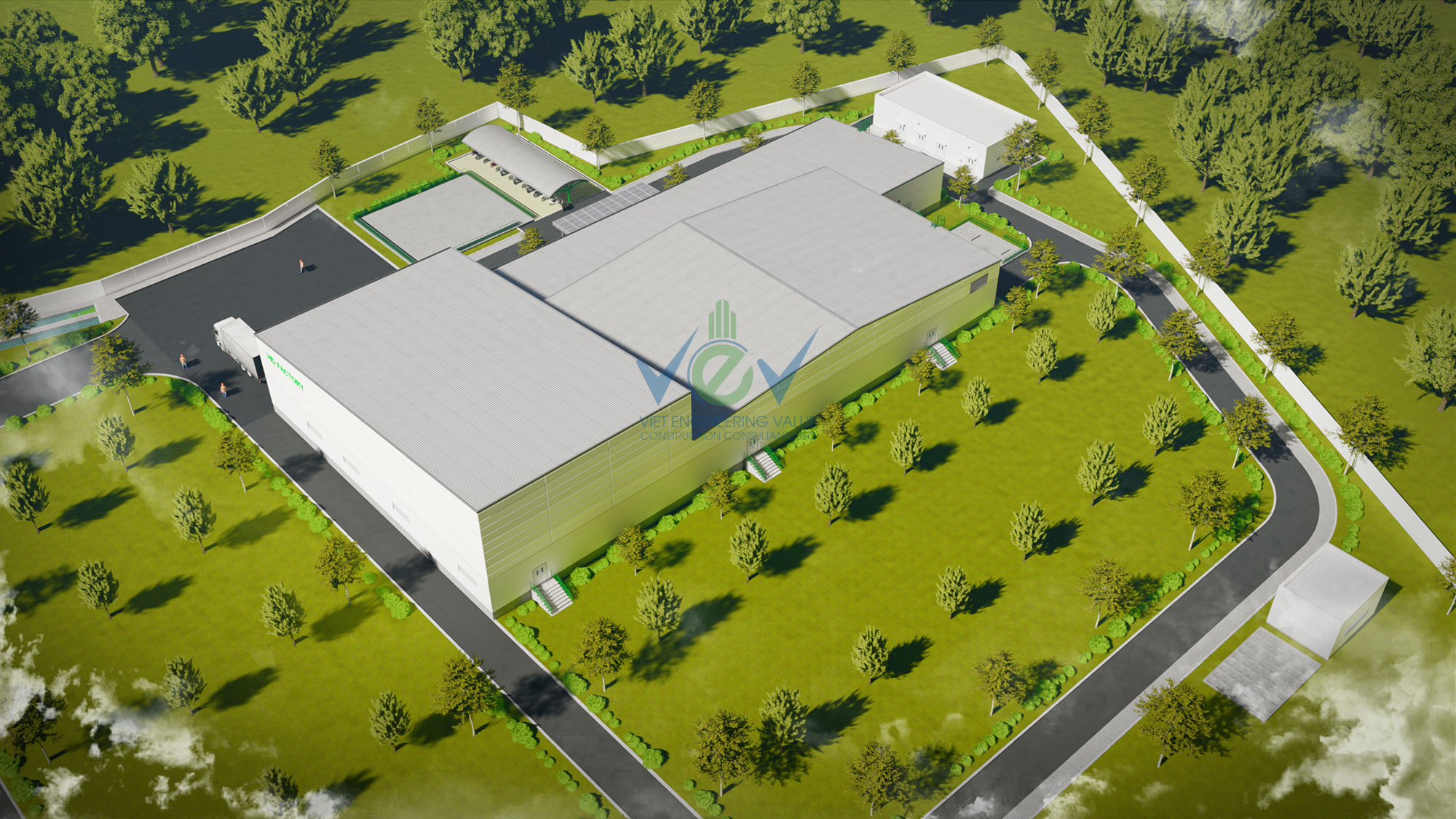

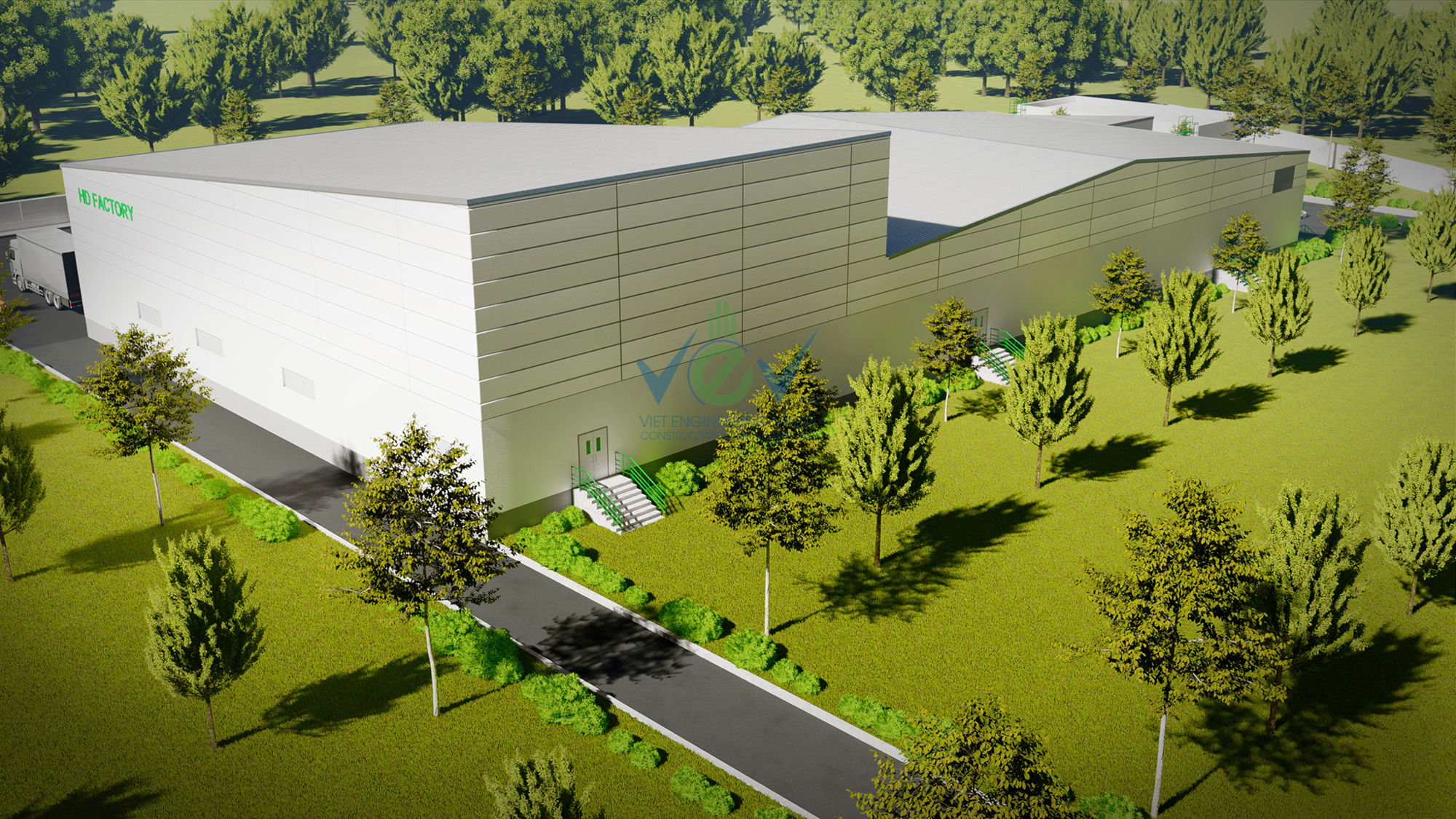

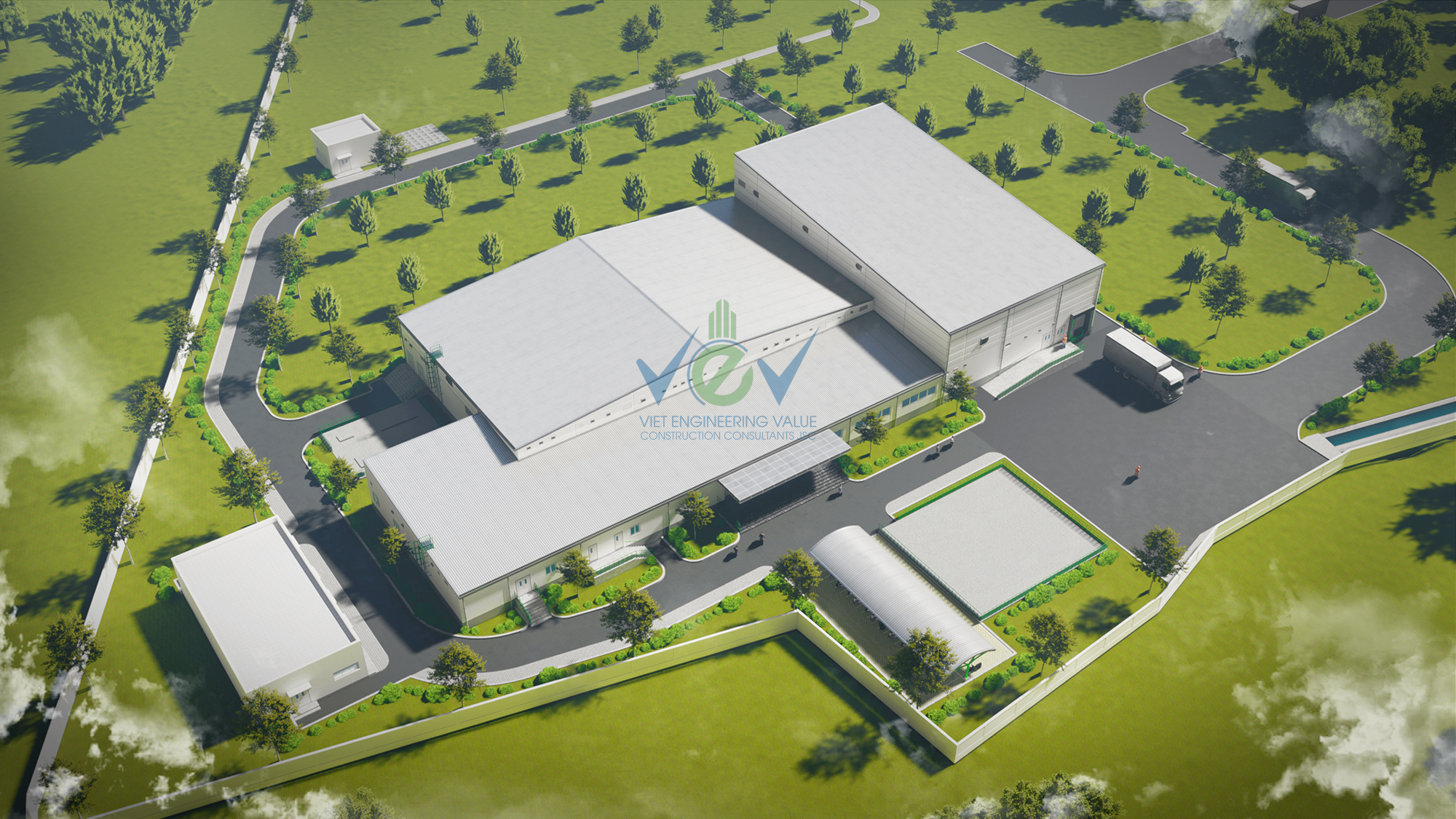

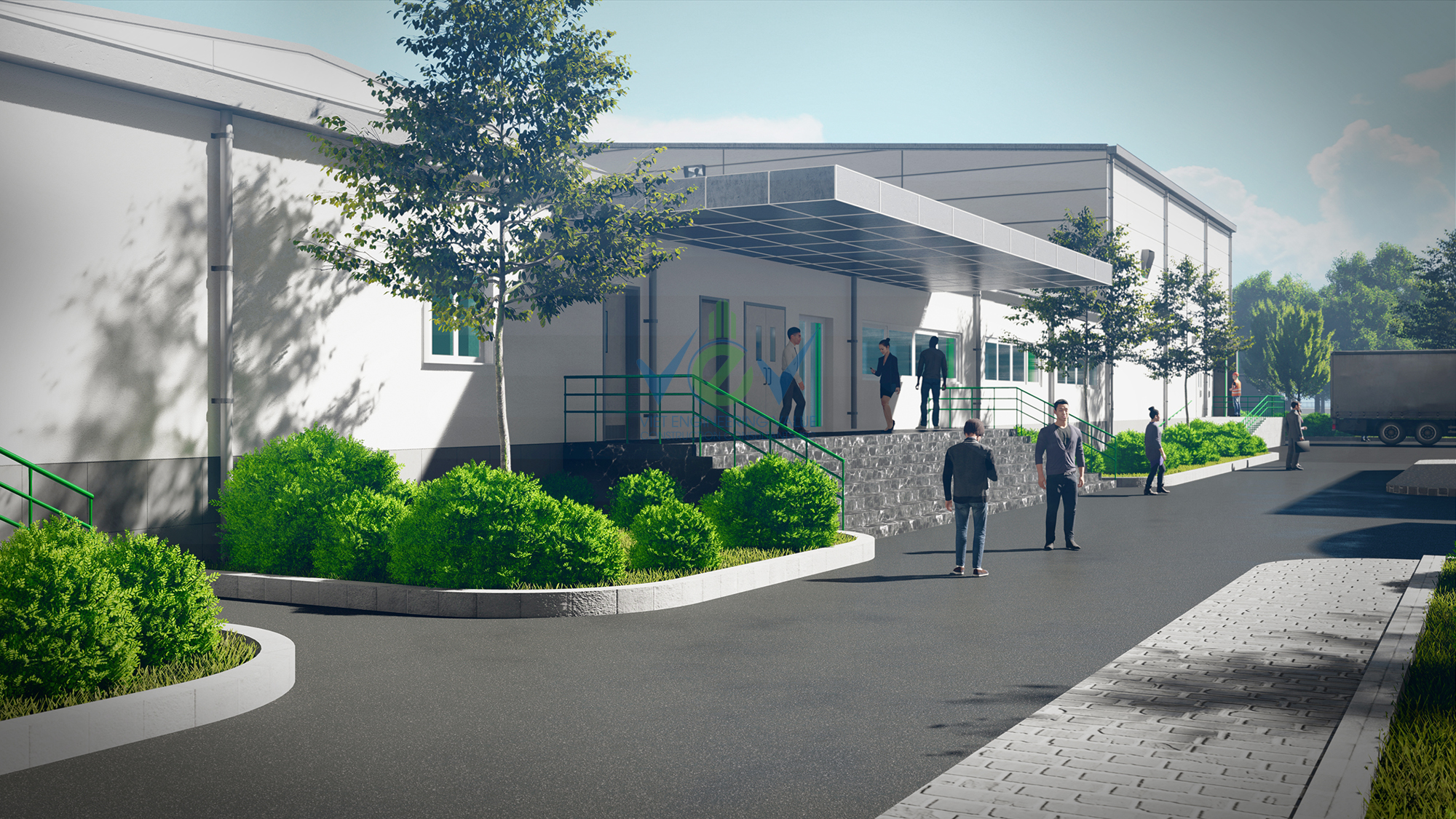

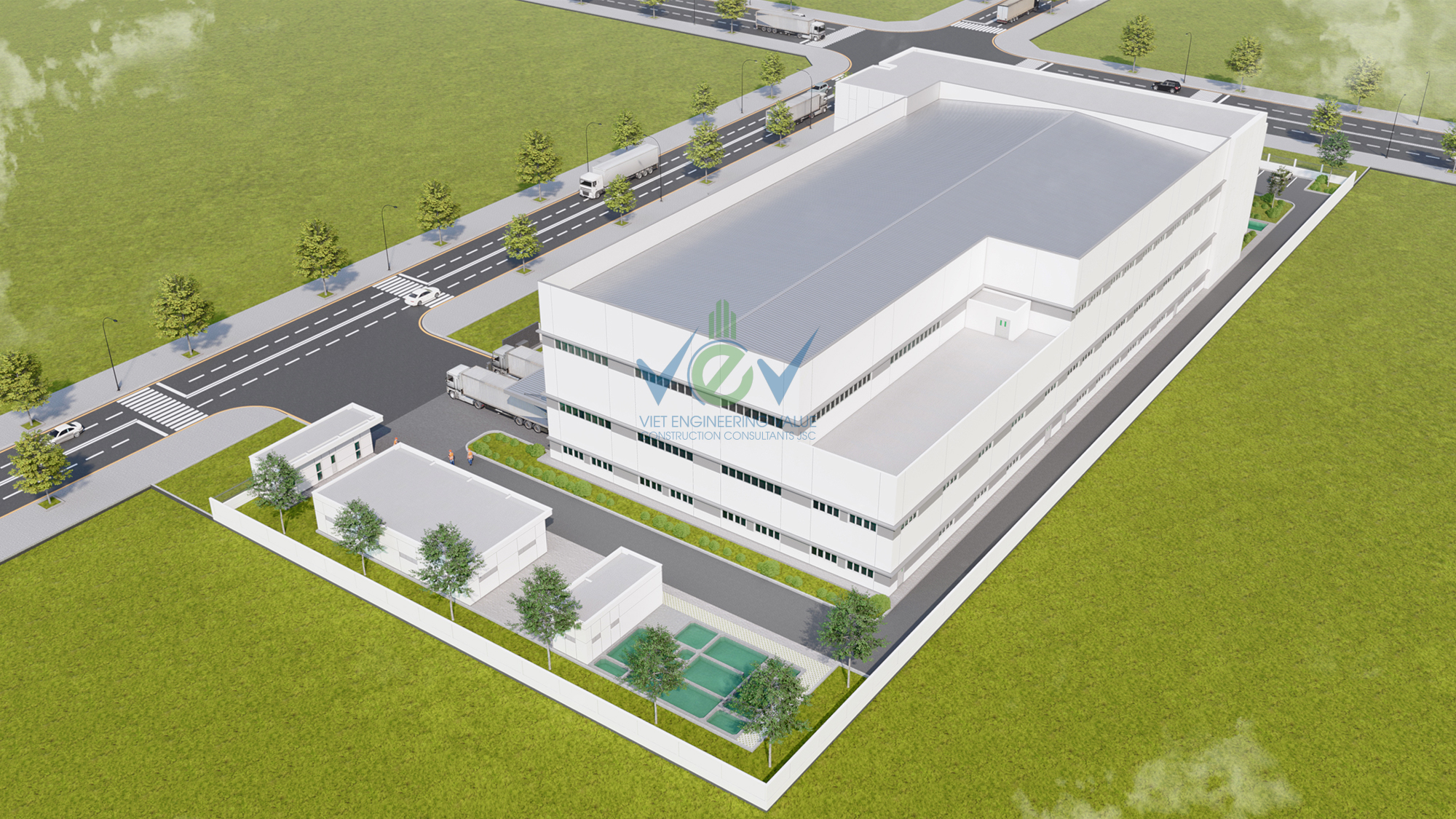

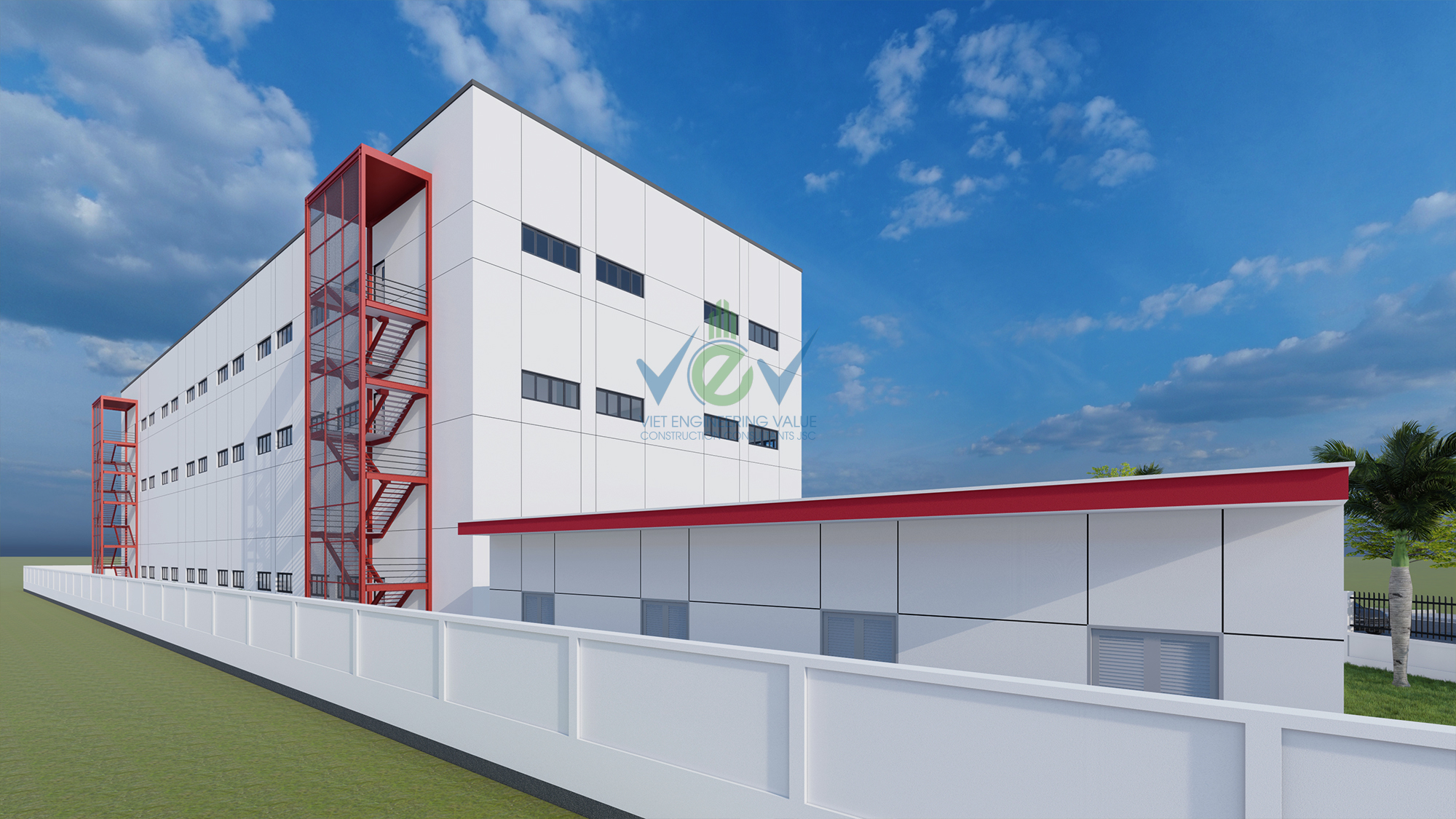

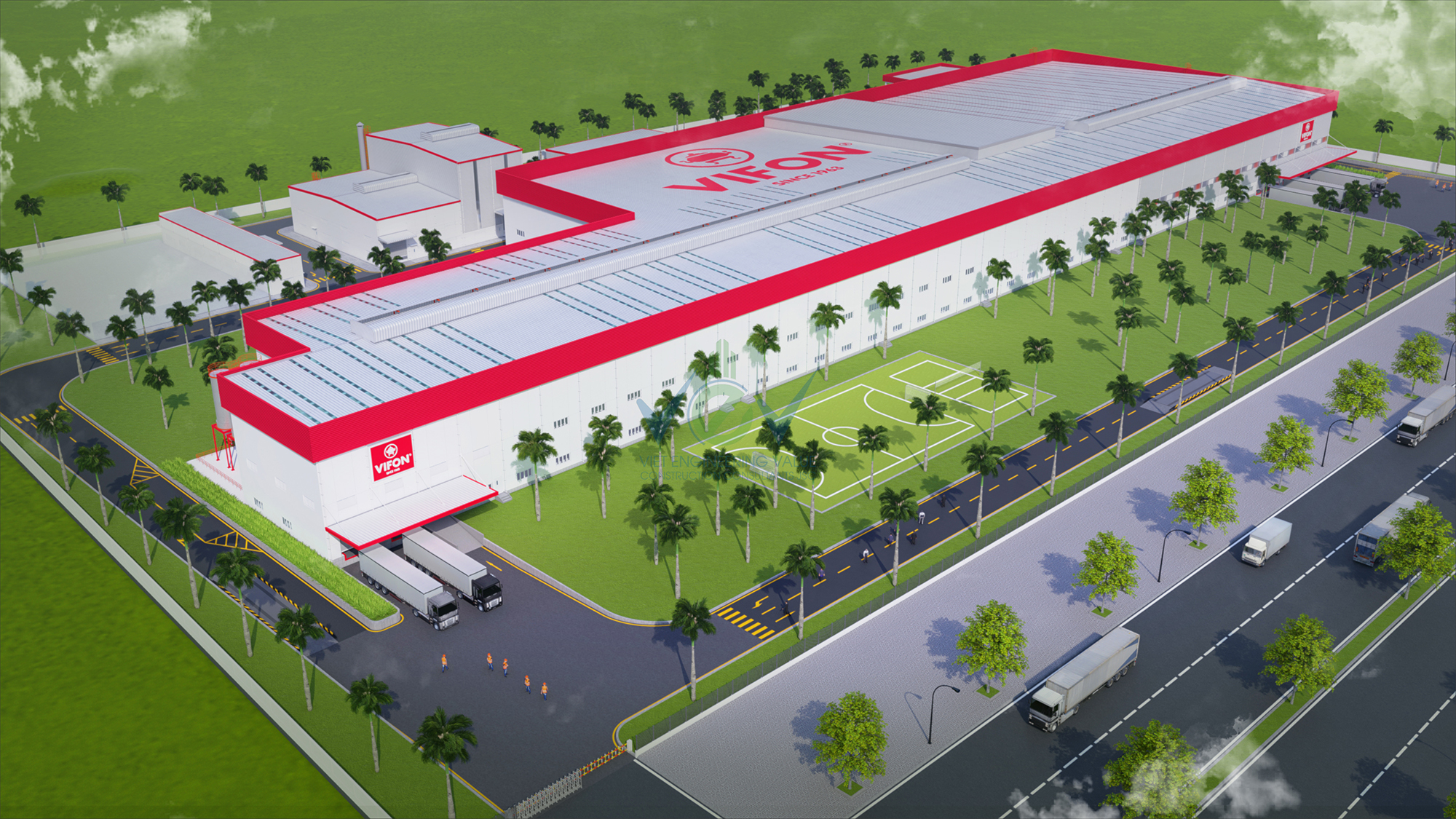

Hình ảnh công trình sau khi xây dựng:

( Source: VEV)

The building had been mentioned in the South East Building Magazine Sep/Oct 2015:

(nguồn: ISSUU.com)

The technical data of DBW building for Sustainability:

ENERGY:

44% of overall energy savings due to a mix of building envelope improvements,

LED lighting and renewables

50% lighting energy reduction from LEDs 30% of energy use is supplied by renewables Commissioning carried out to international standards to improve operating efficiency

TRANSPORT MILES:

electric bike and electric car facilities provided shuttle buses to the local bus stops showers for bicycle users

WATER USE:

40% of water reduction for fixtures

12% recycled water for fixtures

100% recycled water for landscaping

60% of water reduction for process laundry use

ECOLOGY:

85% of the open space is landscaped (due to our green roof concept )

100% localized species with low water requirements overall

Heat Island effect reduced on roof and hard surfaces

Local food production:

Rooftop garden harvest will contribute to worker’s meals

100% capture and reuse of stormwater from roofs and 27% capture and infiltration at ground-level

COMFORT:

Building complies with international ventilation requirements

Comfort is improved with air conditioning in all major working spaces 96% of the working areas have views to the outside

The building is designed to be fully disabled-access compliant

POLLUTION:

Construction pollution controlled on site

No products using Volatile Organic Compounds (VOC’s)

—VOC’s are common toxins found in building products that can off-gas to reduce air quality in the building

Low-greenhouse gas producing refrigerants

No smoking on the premises

MATERIAL USE

42% of all materials are made of recycled content by cost

29% of materials are regional by cost

76% of reduction of use of traditional, highly polluting local bricks

Source : https://deutschebekleidungswerke.com